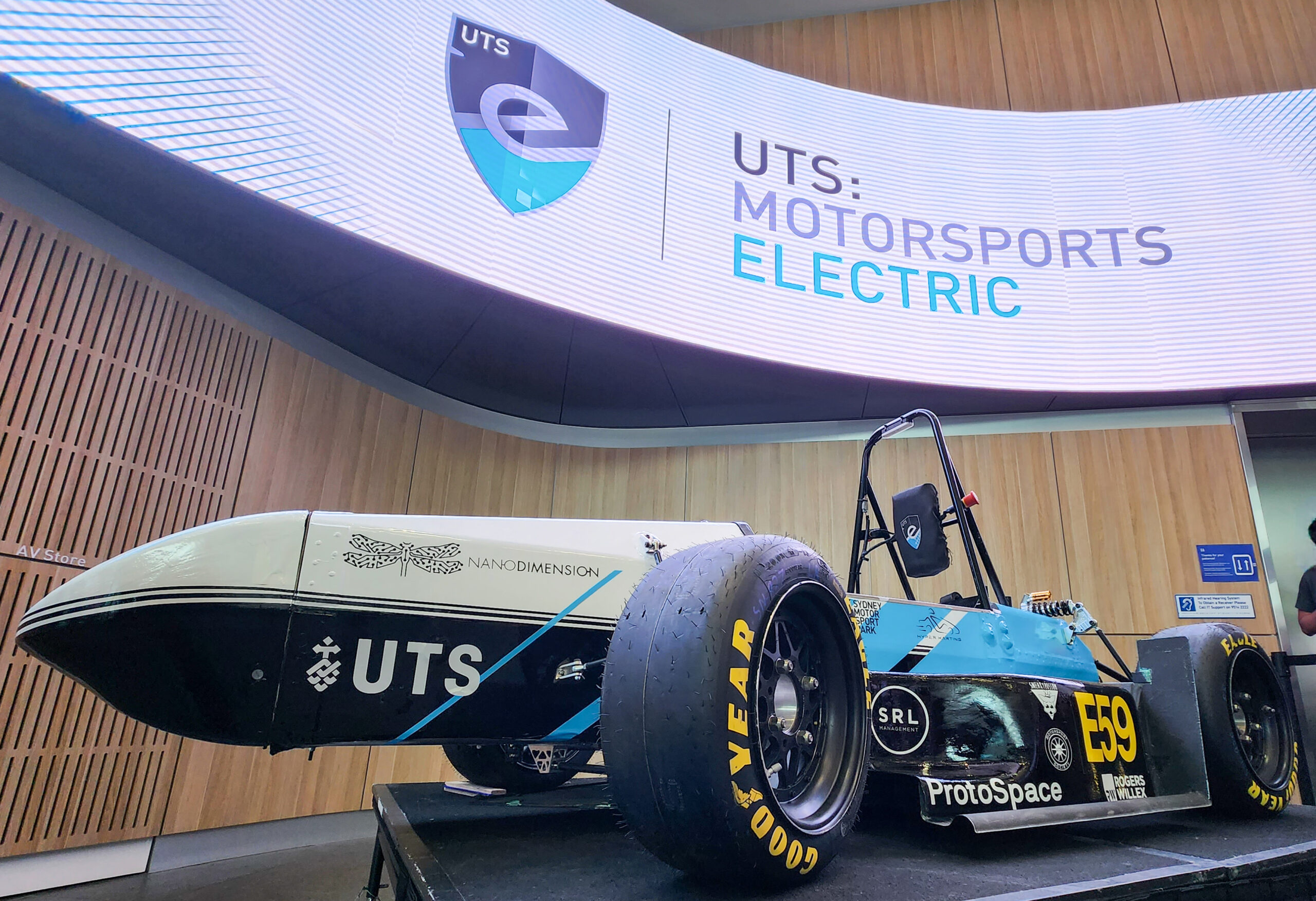

Nano Dimension Partners With UTS Motorsports Electric

Nano Dimension is excited to be part of team UTS Motorsports Electric and to help create the next generation of innovators and leaders.

st

Nano Dimension’s pioneering Additively Manufactured Electronics (AME) allows researchers to rapid prototype functioning circuit boards in a matter of hours.

%

Precision Micro Additive Manufacturing (Micro AM) delivers parts 80% faster than traditional production methods.

%

Self-learning DeepCube neural network-based artificial intelligence (AI) is robust enough to be applied in real time to production machines and is the key driver of Industry 4.0 integrated systems.

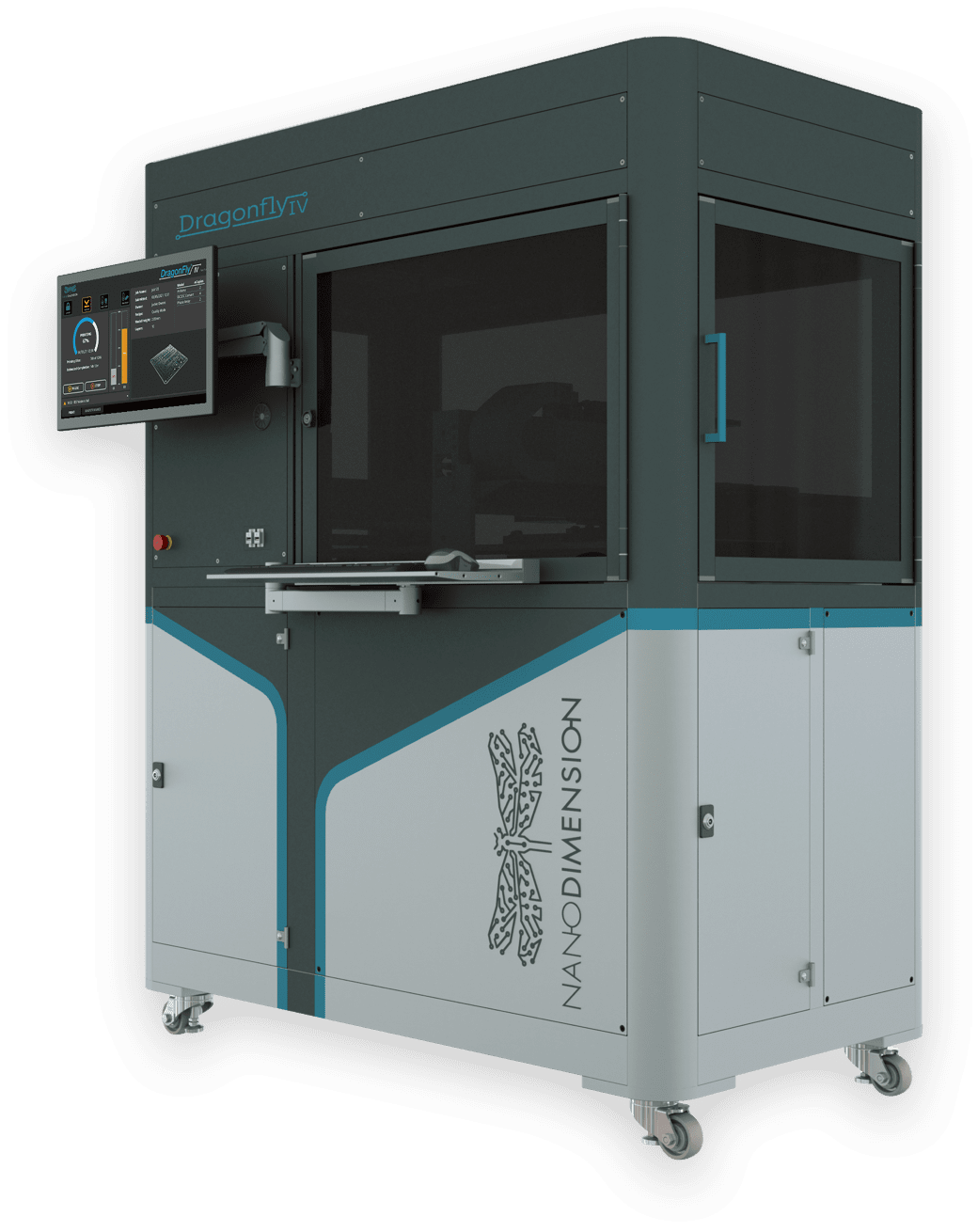

Nano Dimension’s DragonFly prints fully functional 3D electronic circuitry in-house.

Researchers can also explore free-form printing of metals and dielectric polymers for entirely new applications.

Multiply layers and freely form connections inside 3D electronic devices

Fabricate embedded antennas, coils and other high-performance passive components

Immediately test in-house, proofs of concept at low cost