Optimized Component Monitoring

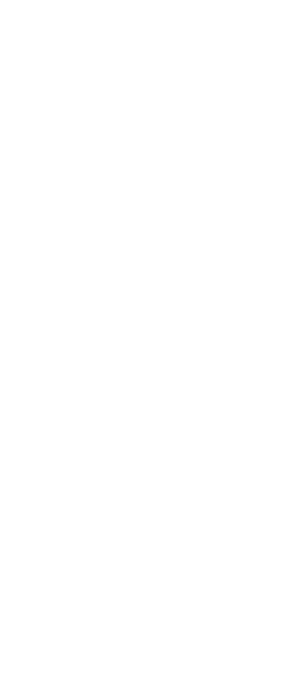

Not just a storage system. Time is money! Especially in the SMT production environment, customers are looking for fast and efficient solutions to ensure the availability of the correct components at the right moment in their production line. Instead of painfully searching for components on a shelf, the Material Storage Solutions provide a fully automatic component storage and retrieval system that saves valuable time.

HIVE

FULL TRACEABILITY

- Delivers strong ROI.

- Supplies the right material at the right time in the right location.

- Can be used as total automated SMD storage solution for small- to mid-size companies as well as automated material replenishment units for high- to super-high speed lines.

Cubus Features:

- Expandability

- Productivity

- Accuracy

- ROI

- Flexibility

- Integration

Multi-Talented Software at Your Fingertips

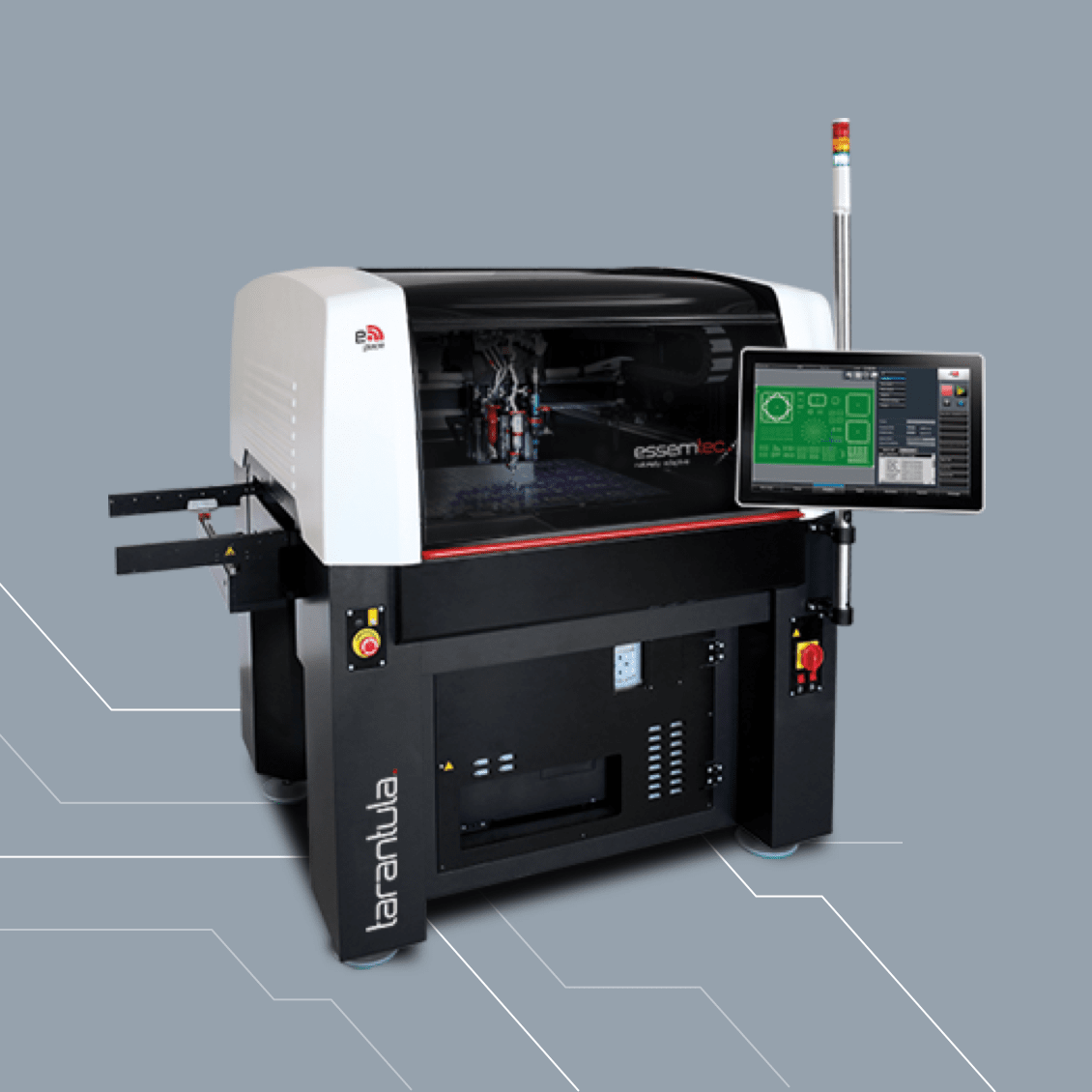

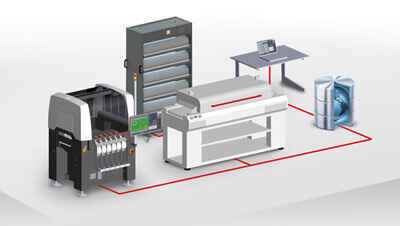

Falcon is ePlace software based on the “eez-technology” architecture and specifically designed for touch screen-based operation (SEMI standards).

Falcon

SMD Equipment Operation Software

- The clearly-structured layout is identical on all screens and contains a large graphical section, combined with parameter and soft key areas.

- All elements are optimized for the use of 21”-wide touch screens.

Falcon Features:

- One software platform for all tasks

- User-friendly

- Real-time information

- Online support

- Latest technology

- Integrates with existing ERP and MES platforms

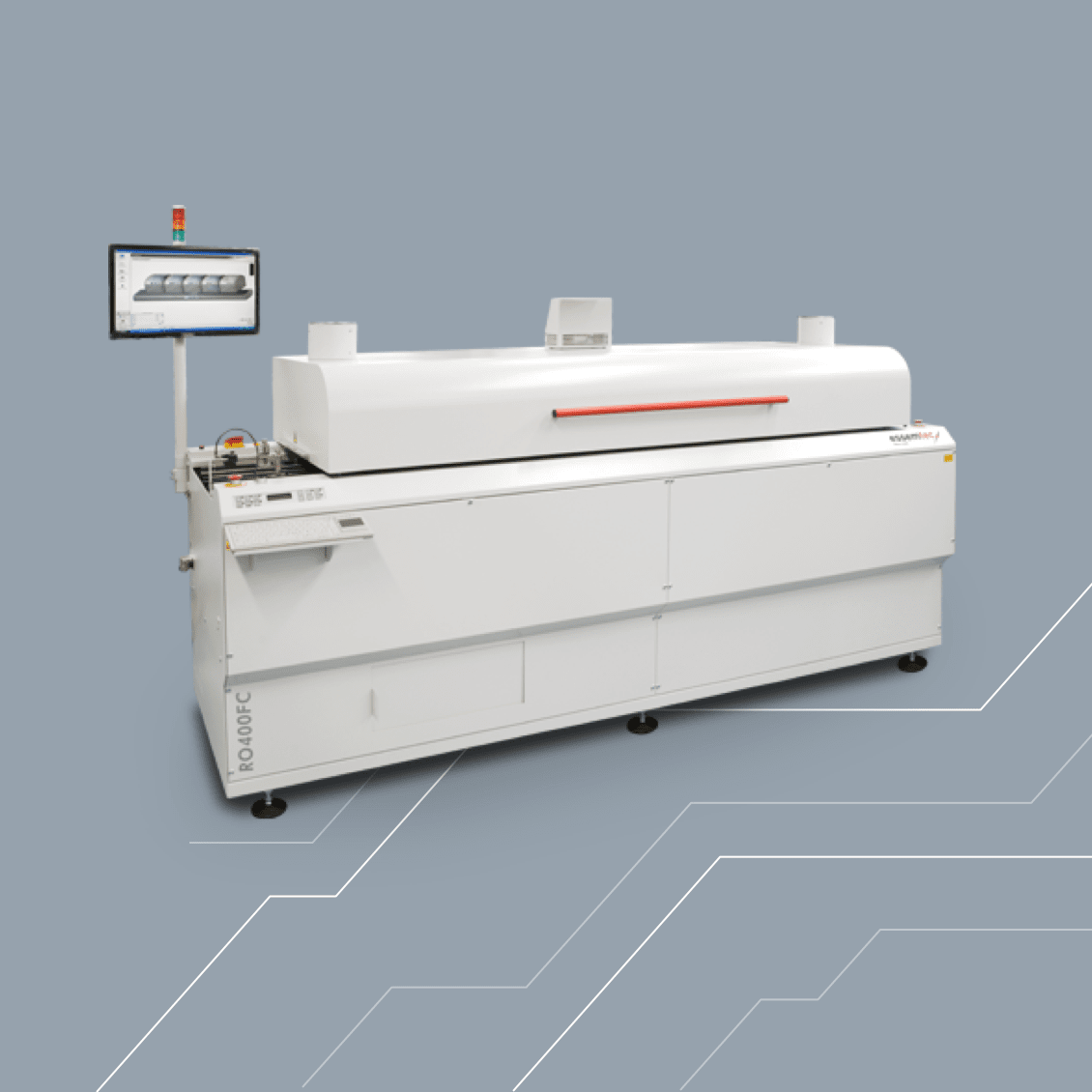

Full Convection Reflow Ovens

Demands for modern ovens are not only in soldering and curing, but in zone regulation, storing of profiles and the extra-high air circulating volume for complex PCB. The RO-Ovens use full convection to heat PCBs homogenously.

Lizard

Reliable Full Convection Reflow Ovens

- RO-Ovens use full convection to heat PCBs homogeneously

- 400 mm process width, integrated microprocessor for profile control and storage

- Optional flying thermocouples, temperature recording directly on the board level guarantee a flawless repeatability of soldering profiles.

Lizard Features:

- Productivity

- Combined process

- Lead-free process

- Controlled process

- Flexible process

- Secure process