How 3D Printing PCBs Aids Impedance Controlled Routing

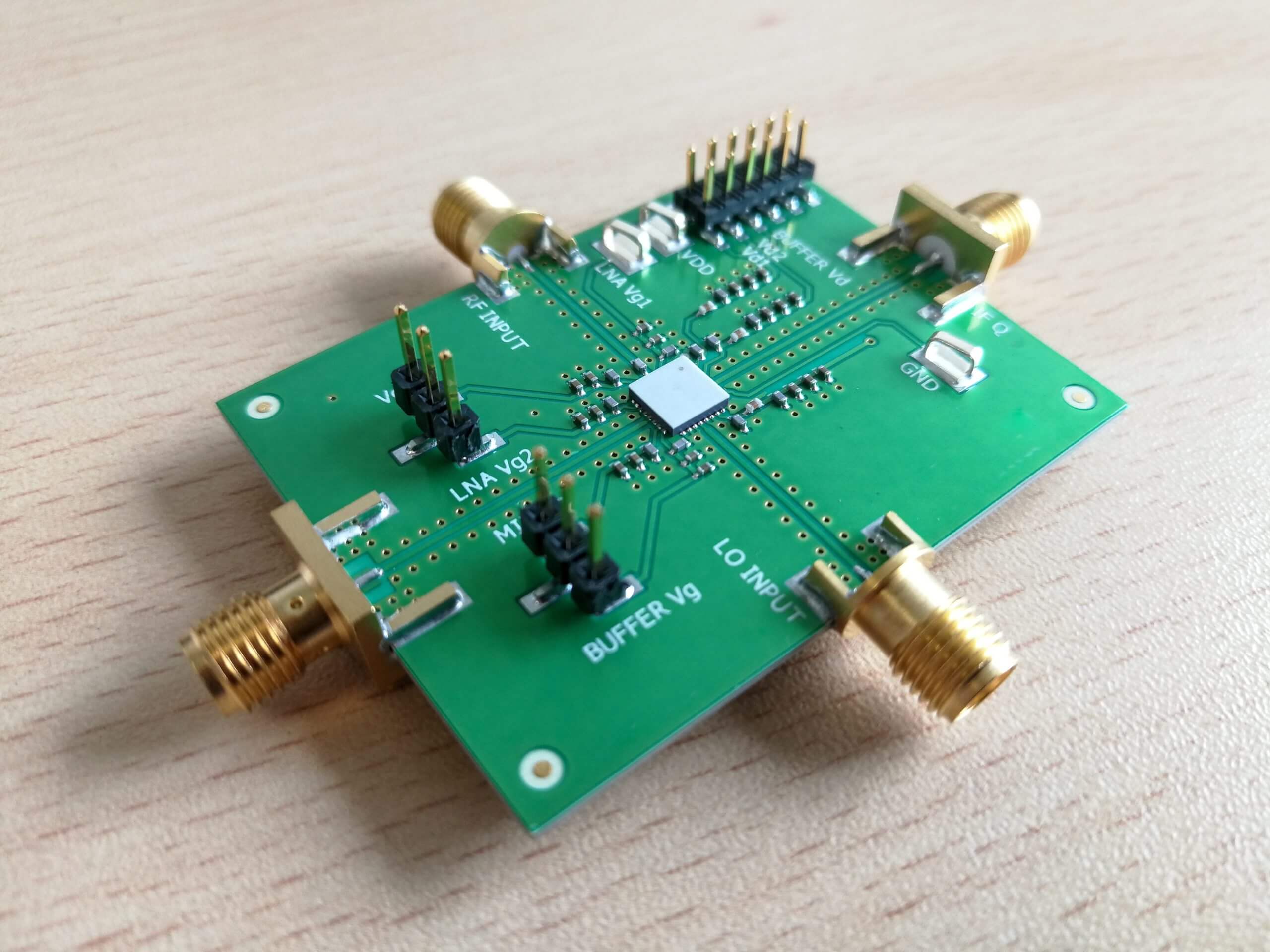

If you’re a designer of extremely high-speed PCBs or high-frequency RF devices, then you’ll be taking advantage of impedance controlled routing features in your PCB design software. These tools are designed to ensure the impedance of a transmission line is consistent along its length, thereby allowing termination at each end to prevent reflections. Consistent impedance…