Sep 21, 2021

Additively Manufactured Multi-Material Ultrathin Metasurfaces

CHALLENGE

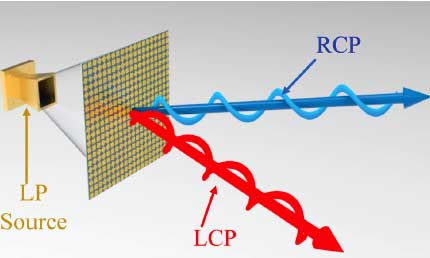

While the use of metamaterials to control linearly polarized wavefronts has been well established, manipulating more geometrically complicated waves with circular polarization has so far proven more problematic.

In contrast to linear polarization, where waves are in the same plane, circular polarization often decouple waves into two opposite 3D helix-shaped paths, one spiraling clockwise, referred to as righthanded circular

polarization (RCP), and its counterpart counter-clockwise or lefthanded (LCP).

The upcoming wireless ecosystem will enable billions of high-speed wireless devices in a These more complex waveforms are of particular interest in research and development since they can carry more information and therefore can significantly increase the channel capacity of wireless communication networks, like 5G.

Using additively manufactured electronics (AME) fabrication technology to create the 3D ultrathin surfaces, Dr. Yang Yang’s group at the University of Technology Sydney (UTS) tested an experimental method to control the path of decoupled circular polarized microwaves while maintaining the informational integrity of their geometric phase.

THE SOLUTION

The DragonFly system manufactured by Nano Dimension, is a comprehensive platform for Additively

Manufactured Electronics (AME). This in-house dual-material 3D printing innovation has been used by UTS in

the development of 5G radio frequency antennas and circuits.

The machine can depose multiple inkjet materials layer by layer – in this case, a conductive silver nano-particle

ink and a dielectric acrylate to provide insulation and rigidity. Dr. Yang’s group worked with Nano Dimension R&D to fabricate a series of layered multi-material surfaces with a grid of small meta-atoms spaced according to the

the amplitude of the electromagnetic radiation.

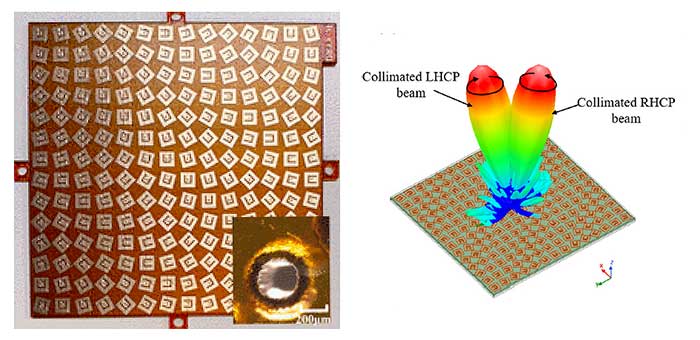

Using two 3D-printed ultrathin metasurfaces, Dr. Yang’s group was successful in shaping decoupled LCP and

RCP wavefronts in the microwave region. Using strip-line with different lengths and in-plane rotating the transmitting antenna, two different phase-shifting techniques were hybridized to decouple the

LCP and RCP waves and shape their wavefronts. The measured results agree well with the numerical

simulations.

KEY ADVANTAGES

The proposed ultrathin configuration cannot be easily achieved using conventional fabrication techniques such as printed circuit board (PCB) due to the assembling challenges.

The advantages of the multi-material additive manufacturing for LCP/RCP decoupled metasurface are low cost and fast prototyping.

The geometric phase-shifting is achieved by only rotating the transmitting antenna rather than in-plane rotating the whole unit cell.

Because the receiving antenna is linearly polarized, the metasurface can be further extended to folded-type metasurfaces. The proposed strategy has the potential to be used to implement other multifunctional devices for polarization beam splitters, Orbital Angular Momentum (OAM) communication, and holograms.

Further, miniaturized element frequency sensitive surface (MEFSS) low-volume manufacturing with AME opens up industry applications in acoustics, sensors, radar imaging, terahertz, and infrared optics, coatings, and films, lidar systems for self-driving cars, and medical imaging.

CLIENT

ProtoSpace of UTS is Australia’s most advanced additive manufacturing facility located in the heart of Sydney.

UTS ProtoSpace provides access to advanced 3D printing and scanning technologies along with specialized technical support, linked education, and engagement opportunities. Dr. Yang Yang is the Principal Scientist and Lead of the Australian 3D Terahertz Beam Measurement Platform. He is also the group leader of Millimeter-Wave Circuits and Antennas at UTS Tech Lab, and currently a principal supervisor of seven Ph.D. students.

To read the technical research paper in full, and see “Additively manufactured Multi-Material Ultrathin Metasurfaces for Broadband Circular Polarization Decouple beams and Orbital; Angular Momentum Generation” published by ACS.

Stay Updated

Be informed of the future of additive manufacturing &

3D printed electronics