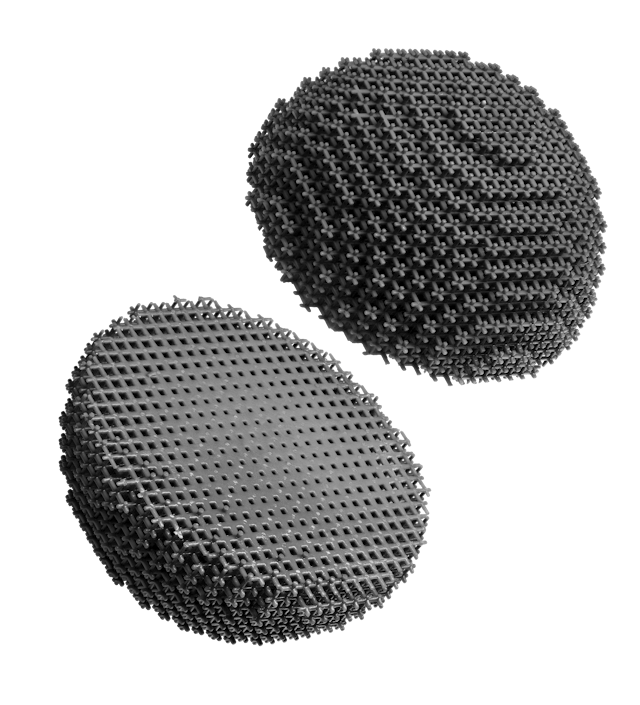

A groundbreaking UV-curable

material for DLP-printing

ATARU™ BLACK is engineered for exceptional high-temperature

resistance and durability. ATARU™ BLACK also delivers excellent surface quality along with incredibly low dielectric loss.

____________________________________________________________________________________________

Market-leading thermal performance and durability

Suitable for injection molding & demanding environmental conditions.

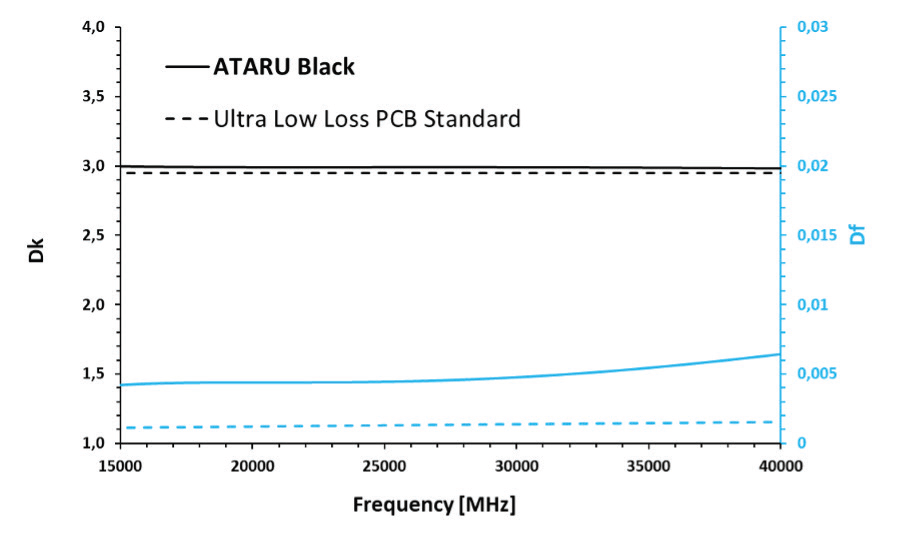

Signal Integrity Assurance

Unique low dielectric loss property ensures suitability for high-frequency electrical applications.

Seamless integration

Low viscosity ensures compatibility with a wide range of DLP printers, enabling reliable printing and consistently high-quality results.

Enhanced Precision

Maintains excellent accuracy, even for fine features, down to the printer’s pixel size. Easily scalable, even after post-processing.

Key Benefits

- High thermal performance and durability

- High impact strength

- Ultra low loss

- Excellent surface quality

- Maintains excellent accuracy, even for fine features, down to the printer’s pixel size.

- Fast processing

- Serial production

Ideal Applications

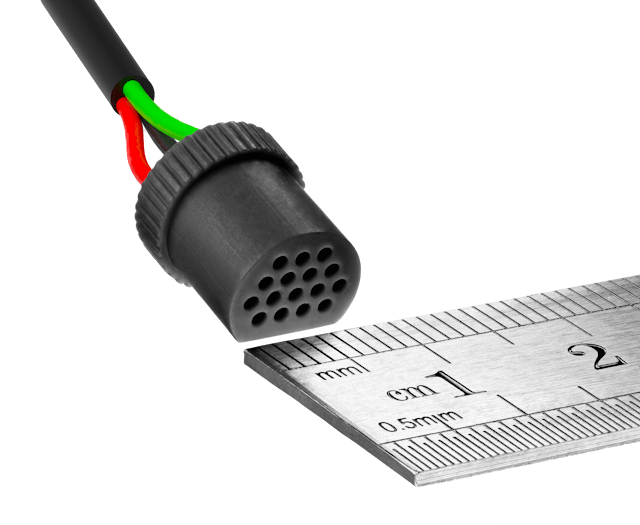

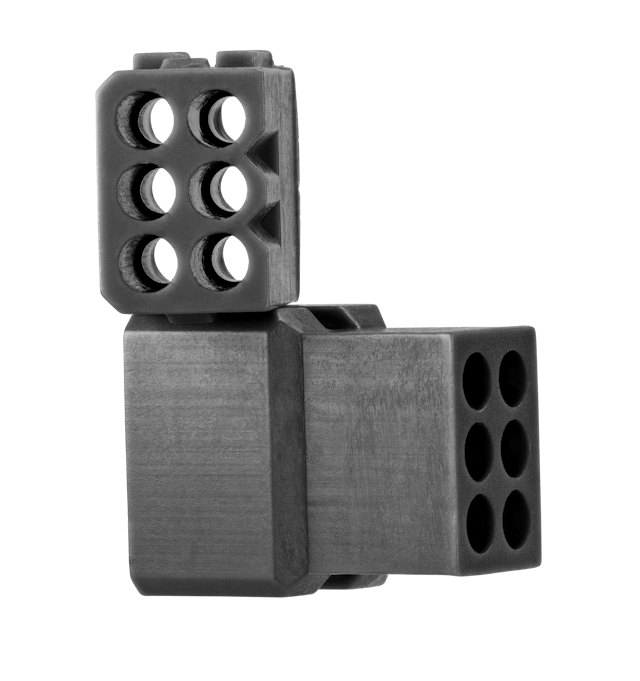

- Connectors for electronics

- Molds (injection molding)

- Molding under high pressure & temperature (carbon fiber molding)

- Tools & fixtures

- Radio frequency (antenna)

ATARU™ BLACK Properties

| Viscosity | ~885 mPas (at 23° and 100 1/s) |

| Color | Black |

| Condition | Standard | Unit | Value | |

|---|---|---|---|---|

| Tensile Modulus | 1 mm/min | ISO 527-1/-2 | MPa | 5790 |

| Strain at break | 5 mm/min | ISO 527-1/-2 | % | 1.8 |

| Stress at break | 5 mm/min | ISO 527-1/-2 | % | 69 |

| Flexural Modulus | 1 %/min | ISO 178 | MPa | 5190 |

| Flexural Strength | 1 %/min | ISO 178 | MPa | 121 |

| Flexural Strain at break | 1 %/min | ISO 178 | % | 2.9 |

| Izod impact strength unnotched | +22°C / 1 J | ASTM D4812 : 2006 | J/m | 170 |

| Condition | Standard | Unit | Value | |

|---|---|---|---|---|

| CTE (0°C to 110°C) | 3 K/min | IPC-TM-650 2.4.24.5 | µm/(m∙K) | 45.6 |

| CTE (110°C to 200°C) | 3 K/min | IPC-TM-650 2.4.24.5 | µm/(m∙K) | 75.2 |

| CTE (200°C to 300°C) | 3 K/min | IPC-TM-650 2.4.24.5 | µm/(m∙K) | 106.1 |

| Td2 | 10 K/min | IPC-TM-650 | °C | 367 |

| Td5 | 10 K/min | IPC-TM-650 | °C | 391 |

| Tg | 10 K/min | IPC-TM-650 | °C | >300°C |

| HDT/B (0.45 MPa) | Flat | ISO 75-2:2013-08 | °C | >300°C |

| HDT/A (1.8 MPa) | Flat | ISO 75-2:2013-08 | °C | >300°C |

| HDT/C (8.0 MPa) | Flat | ISO 75-2:2013-08 | °C | 133 |

| Condition | Standard | Unit | Value | |

|---|---|---|---|---|

| Thermal Conductivity | 25 °C | W/mK | 0.28 | |

| Thermal Conductivity | 50 °C | W/mK | 0.29 | |

| Thermal Conductivity | 100 °C | W/mK | 0.31 | |

| Spec. Heat Capacity | 23 °C | J/gK | 0.97 | |

| Spec. Heat Capacity | 200 °C | J/gK | 1.5 |

Resin

Mechanical

Thermo Mechanical

Thermal

Dielectric