in Space

1

st

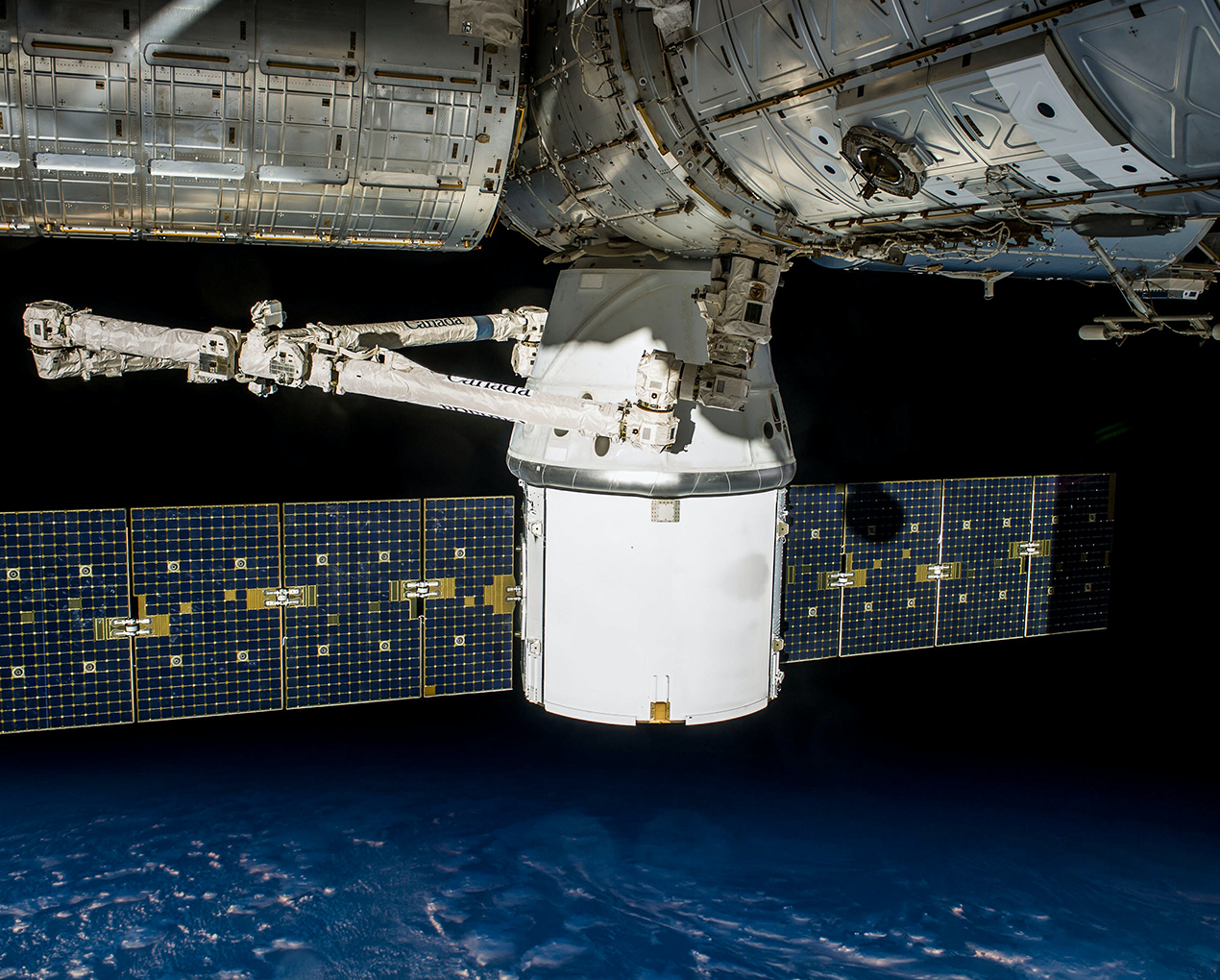

The first additively manufactured RF amplifier launched into space in March 2021

of Potential Applications

100

s

New horizons for additive processes are now emerging in autonomous flight systems, drones, mini-satellites and more

to Proof of Concept

7

Hours

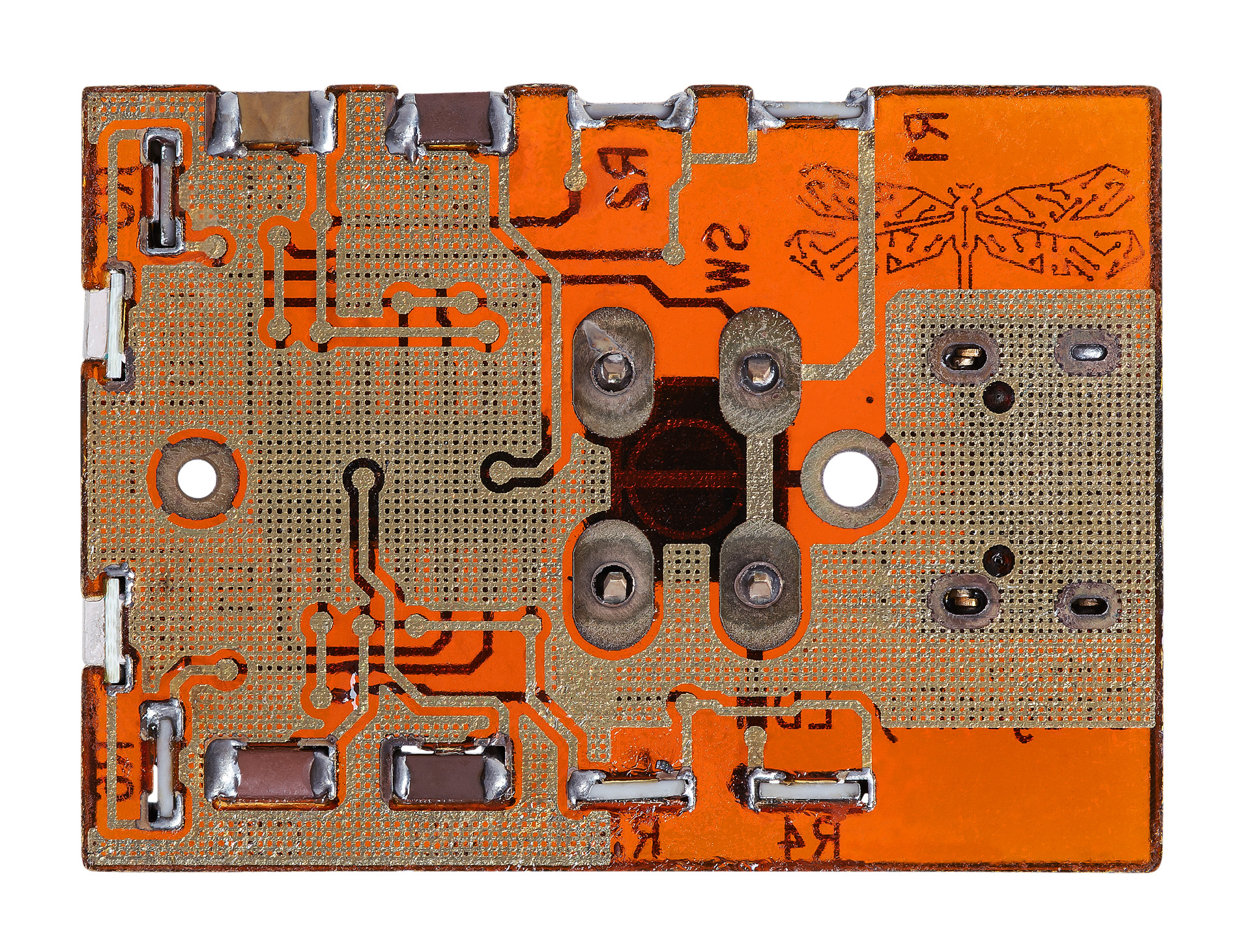

Generate 3D printed electronic circuit board prototypes and micro parts within hours without reliance on outside vendors

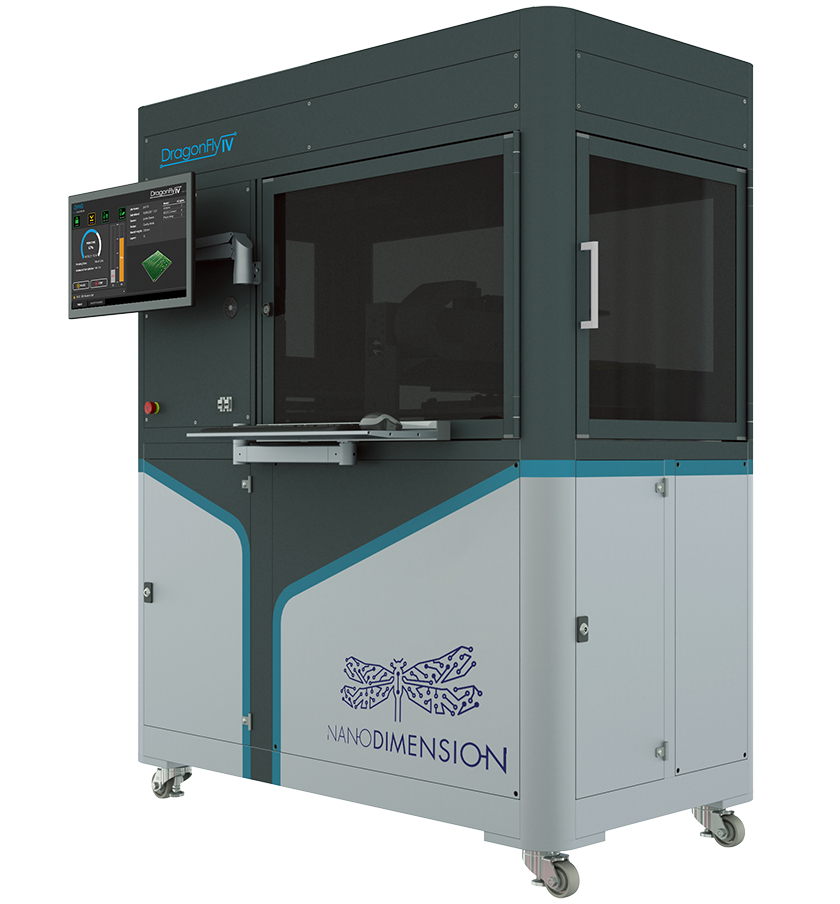

Reinvent Electronics in Your Lab

Groundbreaking technology that gives researchers the freedom to instantly create

Nano Dimension’s DragonFly prints fully functional 3D electronic circuitry in-house.

Researchers can also explore free-form printing of metals and dielectric polymers for entirely new applications.

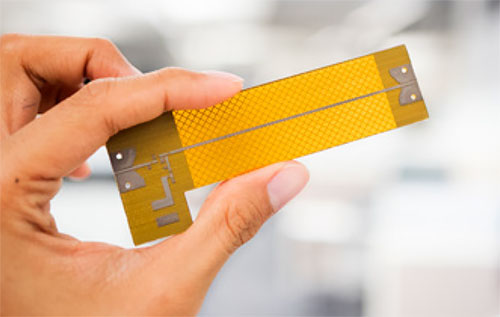

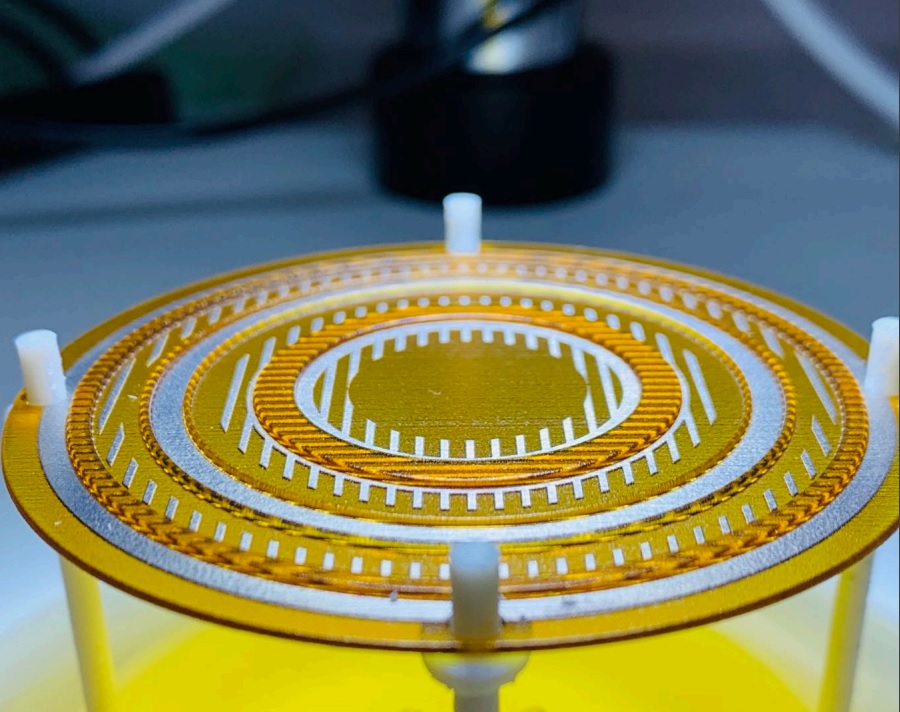

Unprecedented Form Factors

Multiply layers and freely form connections inside 3D electronic devices

High

Performance

Fabricate embedded antennas, coils and other high-performance passive components

Shortened

Development

Cycles

Immediately test in-house, proofs of concept at low cost