Products

AME

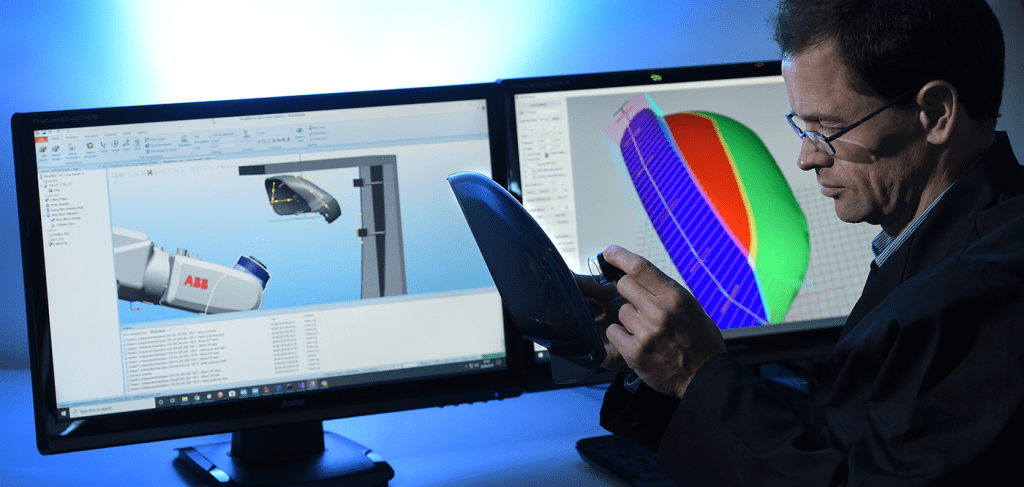

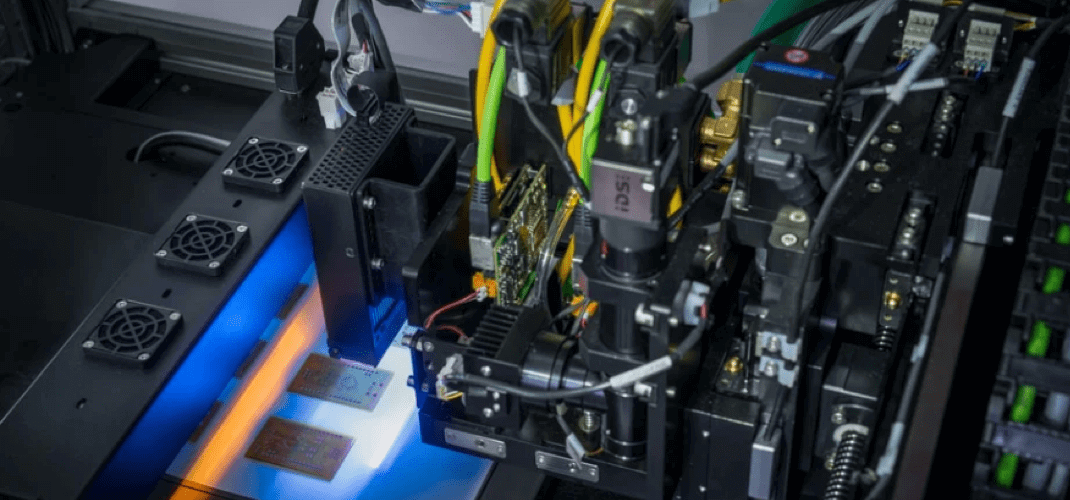

Nano Dimension is peerless in that it is the sole developer and provider of additively manufactured electronics (AME) systems.

The ability to 3D print fully functional circuits and high-performance devices presents the industry with a growing alternative to PCB factory production.