What Is Traditional Investment Casting?

Investment casting, also known lost-wax casting, is a production process where a pattern is used to shape a ceramic mold. A pattern is made in the shape of the part to be cast. This pattern is coated with a ceramic material. Once the material is hardened, it is heated until the wax melts and drains away. The solidified ceramic shell becomes an investment mold. Molten metal is poured into the mold and is cooled. The outer casting is then broken from the spent mold.

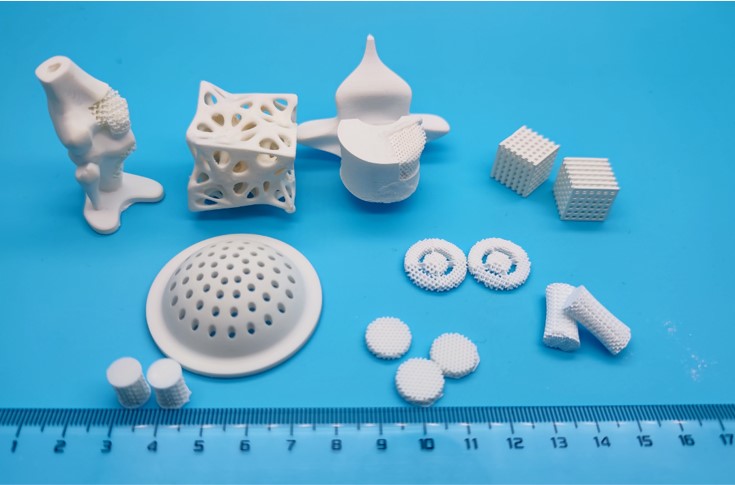

Investment casting is often chosen over other methods due to the resulting casting’s fine detail and excellent surface finish. The final parts can also contain thin walls and complex internal structures. Investment casting does not require a draft (like sand casting).

These properties provide customers with significant cost savings for labor, material and post-processing. Investment casting can make use of many common metals, like aluminum, magnesium, carbon steel, bronze and stainless steel. Investment casting has been used to create everything from medical devices, to jewelry, to turbines and even to sporting equipment like golf clubs.

What Is Investment Casting With 3D Printing?

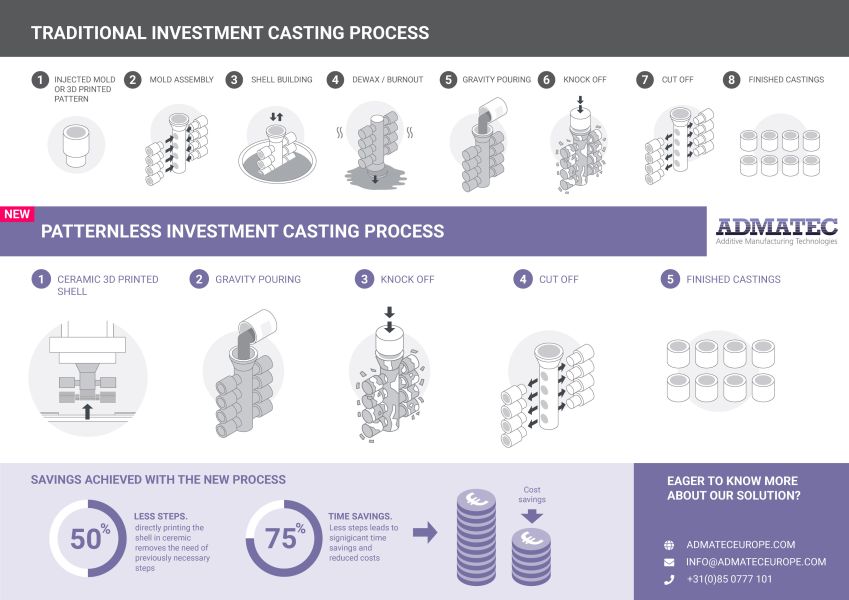

Traditional investment casting is labor-intensive and quite slow. It entails injecting, or 3D printing, a pattern, which is then “invested” in a ceramic material slurry to make the coating for a shell. Each layer has to dry before adding the next.

It can take up to eight coats to finish a shell. Finally, the pattern is burned out from the coating, which leaves behind an opening that is filled with molten metal in order to create a final casting.

The most difficult patterns are those with complex features or cores, as it is difficult to ensure the layer’s integrity and when it is ready to apply the next coat. But with the new process that Aristo-Cast developed with Nano Dimension’s Admaflex 130, it is possible to 3D print the shell directly, which removes steps from the traditional process as well as the need for an expensive injection mold or 3D printed pattern.

When the shell is 3D printed from a CAD file, you no longer have to worry about surface details. The new process can save up to 75% of the time required by traditional investment casting. You no longer need to wait for multiple coats to dry, and it is possible to inspect intricate core passages before you pour the alloy to create the cast.

How Does Investment Casting With 3D Printing Work ?

3D Printing Of A Ceramic Shell

- Mold creation

A gating system (sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, several wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the runner bars, serves to introduce molten metal into the mold.

The assembled “pattern tree” is dipped into a slurry of fine-grained silica. It is dipped repeatedly, being coated with progressively more refractory slurry with each dip. Once the refractory coating reaches the desired thickness, it is allowed to dry and harden; the dried coating forms a ceramic shell around the patterns and gating system.

The thickness of the ceramic shell depends of the size and weight of the part being cast, and the pouring temperature of the metal being cast. The average wall thickness is approximately 0.375 in. (9.525 mm). The hardened ceramic mold is turned upside down, placed in an oven, and heated until the wax melts and drains away. The result is a hollow ceramic shell.

- Pouring

The ceramic mold is heated to around 1000 – 2000°F (550 – 1100°C). The heating process further strengths the mold, eliminates any leftover wax or contaminants, and evaporates water from the mold material.

Molten metal is poured into the mold while it is still hot – liquid metal flows into the pouring cup, through the central gating system, and into each mold cavity on the tree. The pre-heated mold allows the metal to flow easily through thin, detailed sections. It also creates a casting with improved dimensional accuracy, as the mold and casting will cool and shrink together.

- Cooling

After the mold has been poured, the metal cools and solidifies. The time it takes for a mold to cool into a solid state depends on the material that was cast and the thickness of the casting being made. - Shakeout

Once the casting solidifies, the ceramic molds break down, and the casting can be removed. The ceramic mold is typically broken up manually or by water jets. Once removed, the individual castings are separated from their gating system tree using manual impact, sawing, cutting, burning, or by cold breaking with liquid nitrogen. - Finishing

Finishing operations such as grinding or sandblasting are commonly employed to smooth the part at the gates and remove imperfections. Depending on the metal that the casting was poured from, heat treating may be employed harden the final part.

What are the benefits of ceramic injection molding?

CIM applications span a wide range of industries and areas of research.

- Forming net or near net shape parts

- Improving productivity and efficiency

- Lower manufacturing costs

- Improving product performance

High volume production / high degree of reproducibility - Smooth surface finish (no traces of machining like milling)

- Tight tolerances, typically ±0.3% of the dimension

We can achieve even tighter tolerances and higher surface parameters by applying techniques such as 5 axis CNC precision grinding.

What materials are used for ceramic injection molding?

In principle, any ceramic powder is suited for CIM, but at Nano Dimension we specialize in:

- Alumina

- Zirconia

- ATZ

- Electrostatic Discharge Materials (ESD)

What steps are used for ceramic injection molding?

After deciding which ceramic you want to have for your application, the CIM process is as follows:

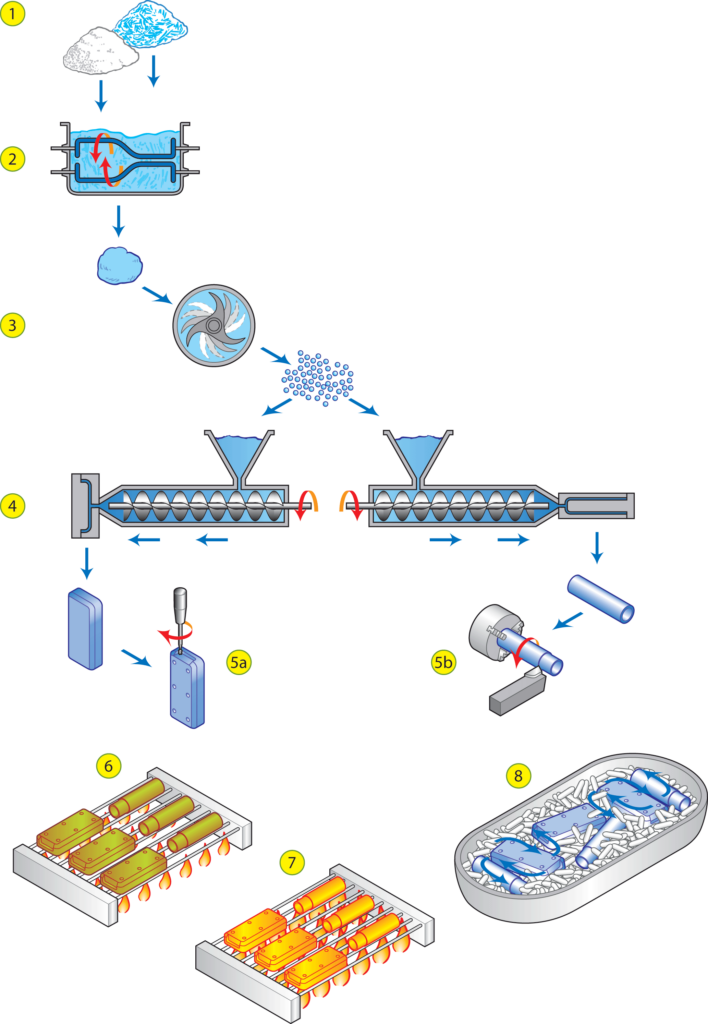

The first step in the ceramic injection molding process begins with very fine ceramic powders which are compounded with polymer binders into a feedstock. During molding, the feedstock plasticizes and is injected with high pressure into the cavity.

After molding, the product is in the green phase where we sometimes apply machining, like removing the injection point or adding features which are not possible with molding.

The next step is removing the binder thermally or chemically in a furnace, thi step is called debinding.

Debinding is followed by sintering. During this step, the ceramic particles fuse together and become a solid piece. The outcome is a fully dense ceramic component. In this final stage, the outstanding ceramic properties have been achieved.

Upon customer request, we can perform additional surface finishing like polishing, sandblasting and lasering for full customization of the parts/products.

With 20+ years of knowledge and experience, CIM has proven to be a reliable manufacturing method if you need volume production quantities of components in a superior material that can withstand physical, thermal, electrical and chemical challenges. It is an effective way producing complex precision parts with a high grade of repeatability and reproducibility.