Discover the possibilities modern SMT gluing provides

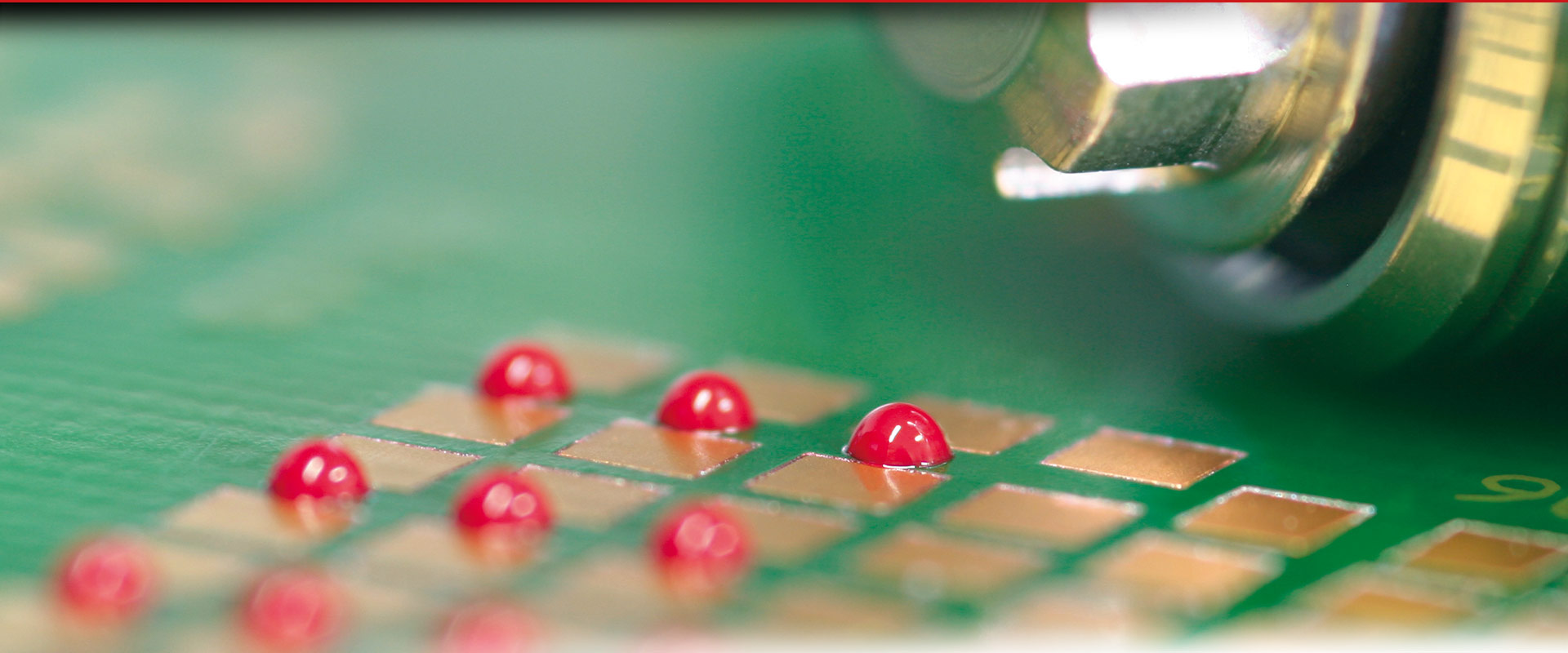

Glue dispensing processes are seeing a renaissance in today’s electronic manufacturing, driven by the need to place and keep components at a predetermined location, such as in LED lamps, and the requirement for miniaturization, increased mechanical reliability and ease of manufacturing of combined SMT/THT boards.

The industry has overcome these restrictions with modern jet dispensing technology and specially formulated fluids which offer fast, dependable, and cost-efficient processes.

Designers can shrink pad geometries, place heavy components on both sides of the board and gain valuable footprint when relying on SMT glue dispensing. Expensive selective soldering processes can equally be eliminated. The glue dispensing process is quick, reliable and has a big process window for dot shapes and size.

Our new white paper details today’s process capabilities and application of modern SMT glue.

Essemtec, a Nano Dimension division, has demonstrated these capabilities on its SPIDER high-speed jet dispenser.

Please complete this form to download the whitepaper now.