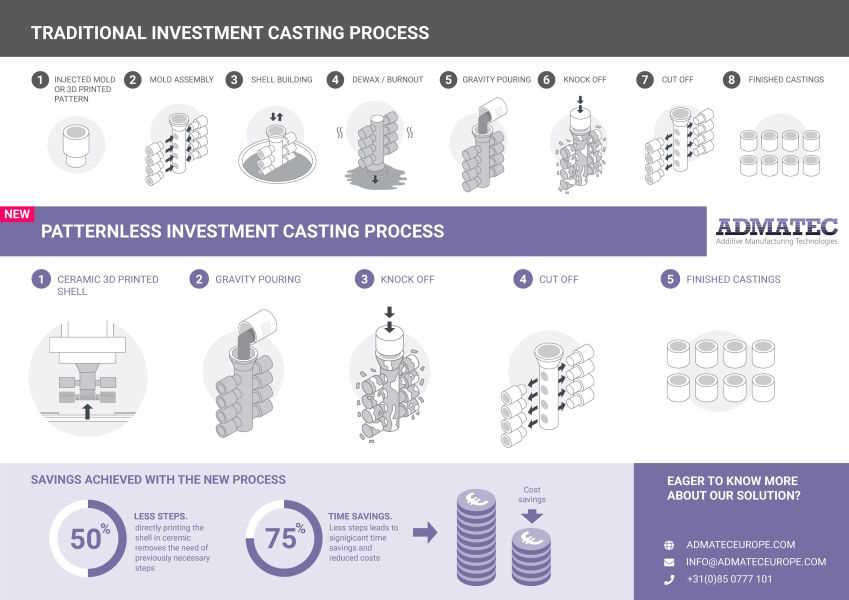

Improving conventional investment-casting technologies by incorporating 3D printing helps achieve better, faster results, lower costs and reduce labor. And while 3D-printing is already used widely to produce casting patterns, additive manufacturing can help further eliminate the existing limitations to complexity, accuracy, and lead time.

Additive manufacturing technologies are rapidly evolving and their applicability to investment casting is growing with it. The most innovative projects can benefit from directly printing silica-based shells and cores, without the need for a wax pattern.

Bring yourself up to speed on this emerging technology by downloading a 16-page eBook, free from Admatec.

The eBook covers the current challenges, the processes, materials, and techniques used to generate successful investment castings via additive manufacturing, a use-case study highlighting a leading company, and systems available today to help businesses adopt this technology.

Get the full picture by downloading the free eBook today – simply complete the form at right and submit!