Jun 17, 2024

The Role of 3D Printed Electronics in Revolutionizing Quantum Sensor Research for Universities and Research Labs

Fostering Innovation in Quantum Sensors

Quantum sensors, with their unparalleled sensitivity, are poised to revolutionize various fields, from medical technology to autonomous navigation and renewable energies. These sensors are at the forefront of quantum technology, offering measurement capabilities that approach the theoretical limits of sensitivity. However, the development and deployment of quantum sensors often require sophisticated equipment and resources that many universities and research labs lack. 3D printed electronics, exemplified by the DragonFly IV system used by institutions like the University of Stuttgart and the BMBF Cluster4Future QSens, are transforming this landscape, democratizing access to advanced research tools and fostering innovation in quantum sensor technology.

3D Printed Electronics: An Overview

3D printed electronics involve the use of additive manufacturing techniques to create complex electronic components. This technology allows for the rapid prototyping and production of electronic non-planar circuits and advanced packaging, including those with intricate designs and custom specifications. Systems like DragonFly IV enable the integration of conductive and dielectric materials in a single print process, facilitating the creation of multi-layer PCBs or non-planar electronics, including printed passives, antennas, sensors, and the heterogeneous integration of other components active or optical in compact devices with high packaging density.

University of Stuttgart and QSens: Pioneering Quantum Sensor Research

The University of Stuttgart, under the leadership of Dr. Jens Anders and the BMBF Cluster4Future “QSens – Quantum Sensors of the Future,” are at the vanguard of quantum sensor research. QSens aims to bridge the gap between basic research and industrial application, fostering collaboration between academia and industry. PhD students and researchers are leveraging 3D printed electronics to push the boundaries in various applications, including coil manufacturing for magnetic resonance imaging (MRI) and the heterogenous integration of miniaturized, diamond-based quantum sensors for human machine interfaces.

Advancements in Coil Manufacturing for MRI

Magnetic Resonance Imaging (MRI) requires highly sensitive and precisely manufactured coils to detect the faint magnetic fields generated by atomic nuclei. Traditional coil manufacturing processes can be cumbersome, expensive, and limited in design flexibility. 3D printed electronics offer a transformative approach by enabling the rapid production of custom-designed coils with optimized geometries and material properties. This flexibility not only enhances the performance of MRI systems but also reduces development time and costs, making advanced MRI technology more accessible to research institutions.

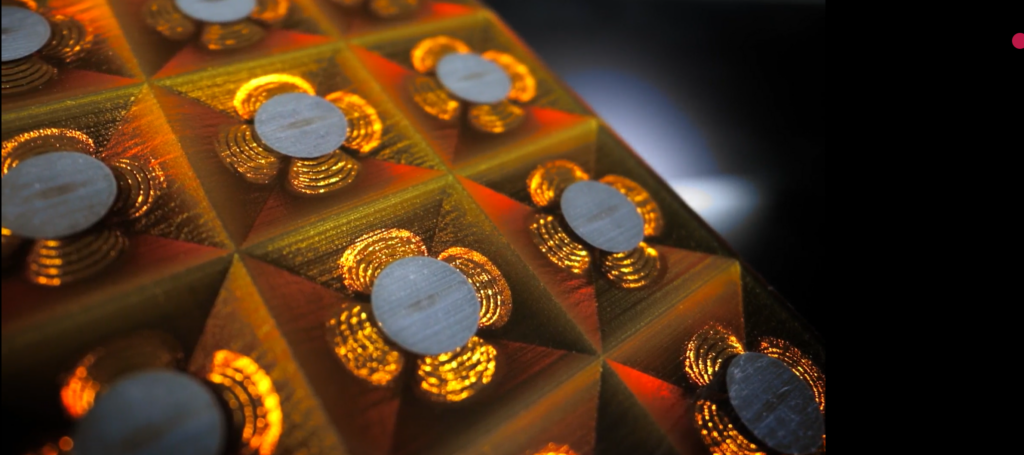

Heterogeneous integration of quantum sensors using 3D printing

Sensors based on nitrogen-vacancy centers (NV centers) in diamond can measure the tiny magnetic field produced by the neural current in muscles and even the brain. However, the relatively large size and cost of such devices is one limiting factor that currently prevents a wider market entry. Here, heterogeneous integration using 3D printed electronics presents a very promising avenue to improve sensor size, scalability, and costs, paving the way towards diamond-based quantum sensors that can, e.g., control prosthetics or help locked-in patients.

Democratizing Quantum Sensor Research

The adoption of 3D printed electronics by institutions like the University of Stuttgart and QSens underscores a broader trend toward democratizing access to cutting-edge research tools. For universities and research labs, the ability to produce sophisticated electronic components in-house represents a significant shift. This accessibility empowers researchers to innovate rapidly, iterate designs, and conduct experiments without the constraints imposed by traditional manufacturing methods.

Cost and Time Efficiency

Traditional manufacturing of electronic components often involves lengthy and costly processes, including multiple stages of design, prototyping, and testing. 3D printed electronics streamline this process, allowing for rapid prototyping and immediate testing of new designs. This efficiency reduces the time and financial barriers associated with developing and refining quantum sensors, enabling institutions to compete with larger, better-funded counterparts.

Customization and Innovation

The versatility of 3D printing technology allows researchers to experiment with novel designs and materials that would be difficult or impossible to achieve with conventional methods. This capability fosters innovation, enabling the creation of bespoke components tailored to specific research needs. For quantum sensor development, this means the ability to design sensors with unique properties that enhance sensitivity, accuracy, and functionality.

The Future of Quantum Sensor Research in Germany

Empowering Innovation with Additive Manufacturing of Electronics introduces a paradigm shift in design possibilities, QSens is not only advancing the field of quantum sensors but also establishing a regional ecosystem for their industrial production. By integrating research efforts with industry partnerships, QSens is positioning Germany as a leader in quantum sensor technology. The development of a robust infrastructure for quantum sensor production will ensure that these advanced technologies are accessible and beneficial to a wide range of applications, from healthcare to renewable energy.

3D Printed Electronics are Revolutionizing Research

3D printed electronics are revolutionizing the research and development of quantum sensors, particularly for universities and research labs that lack access to major equipment and facilities. Through the pioneering work of institutions like the University of Stuttgart and QSens, these technologies are becoming more accessible, fostering innovation and accelerating the development of quantum sensors. As 3D printed electronics continue to evolve, they will play an increasingly crucial role in democratizing advanced research and enabling breakthroughs in quantum sensor technology.

You might also be interested in

Stay Updated

Be informed of the future of additive manufacturing &

3D printed electronics