3d printing | AME

Jun 17, 2024

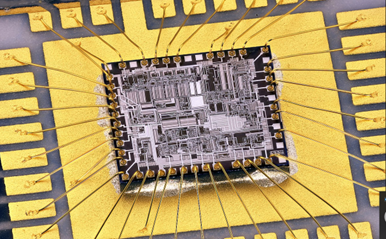

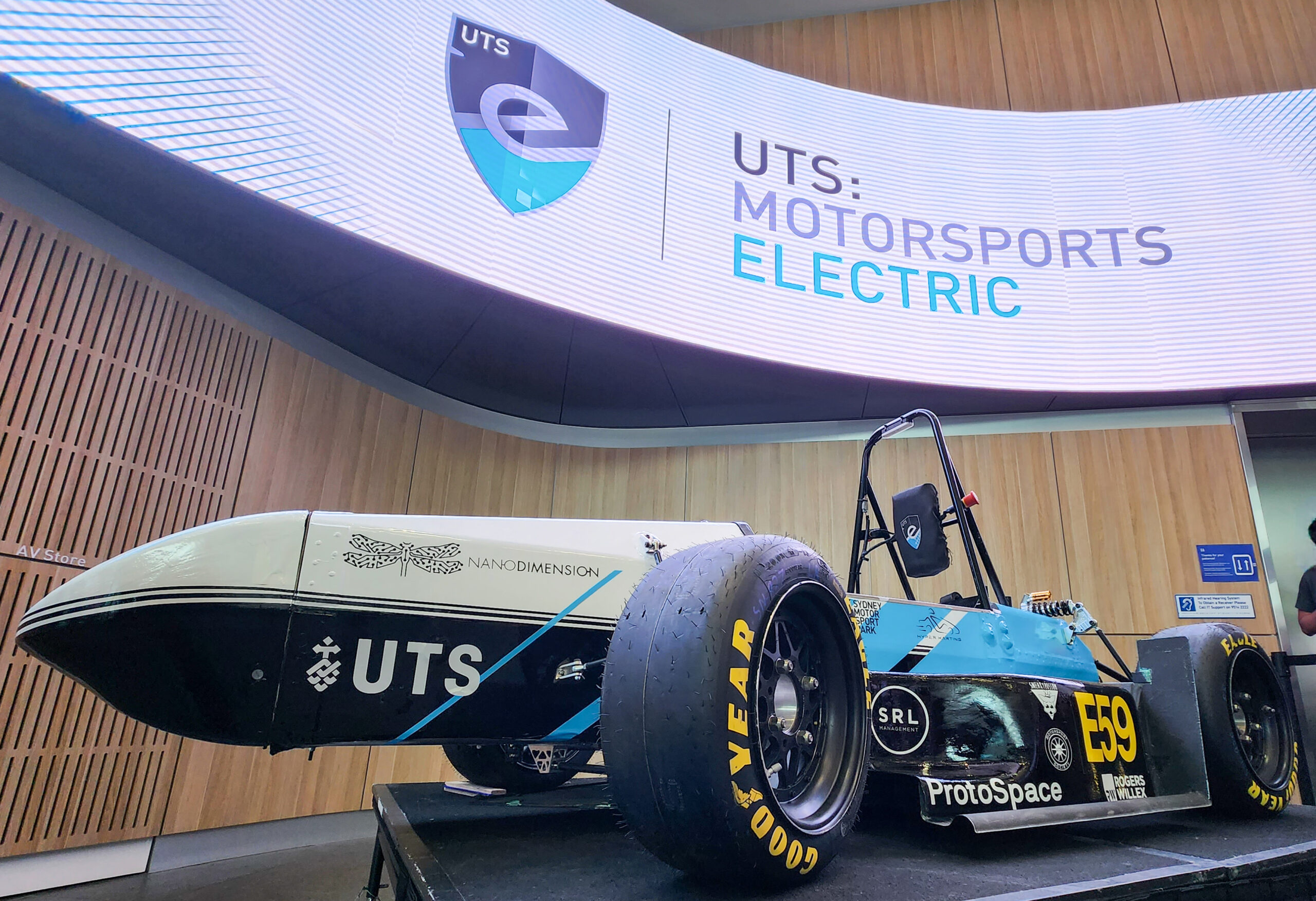

The Role of 3D Printed Electronics in Revolutionizing Quantum Sensor Research for Universities and Research Labs

Quantum sensors, with their unparalleled sensitivity, are poised to revolutionize various fields, from medical technology to au...