Possibilities made endless with concurrent multi-material 3D printing

Molded Interconnect Devices (MIDs) provide for a high degree of design flexibility and potential for miniaturization, since conductive wires are built directly onto dielectric frames instead of having to be enclosed within an insulating structure.

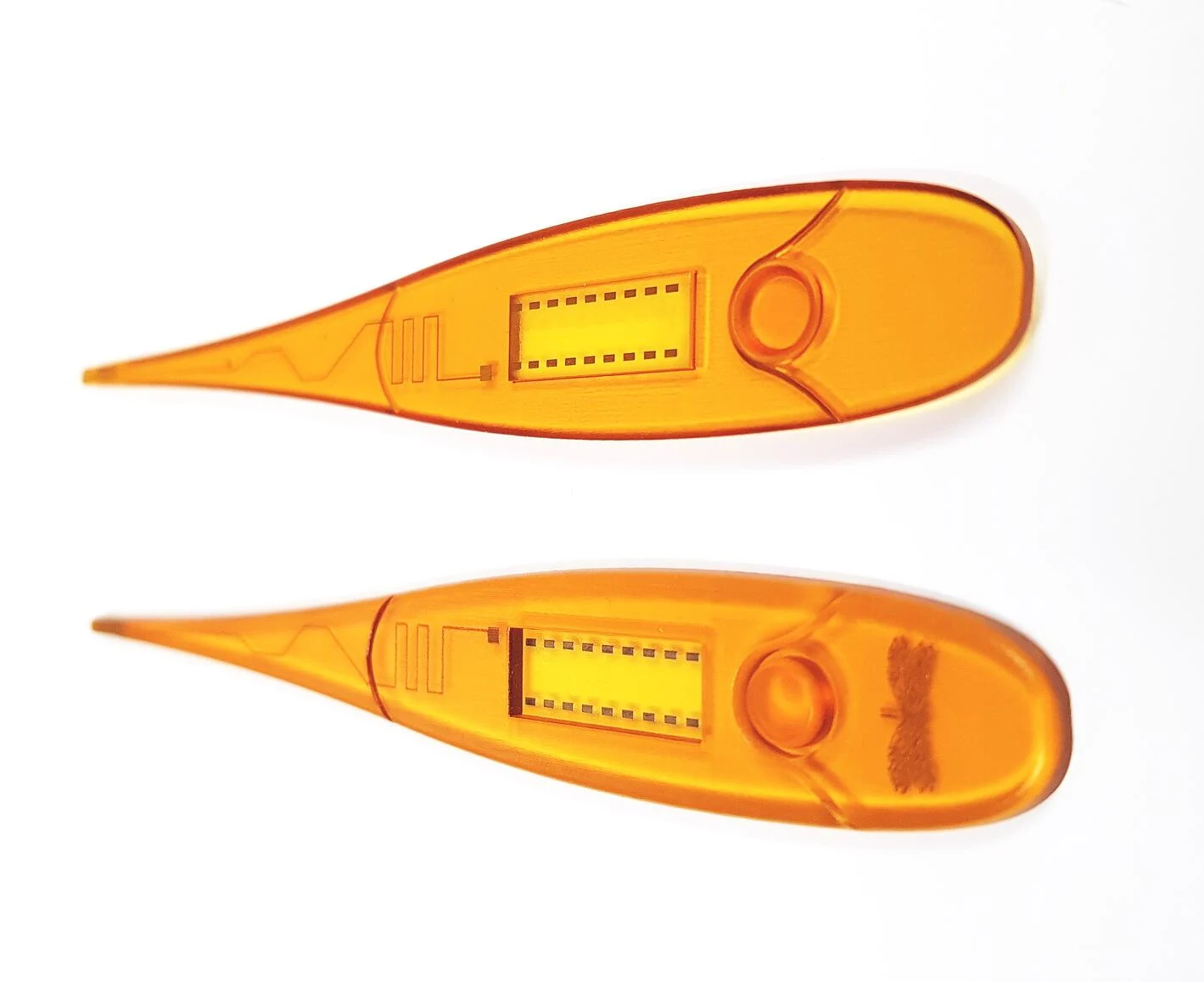

With the DragonFly 3D printer’s ability to print both dielectric and conductive inks concurrently, not only is production time kept low, but conductive traces can now be printed within insulating materials – providing even greater benefits and room for creativity.