From additive manufacturing to robotic assembly and finishing, Nano Dimension production solutions can transform your process

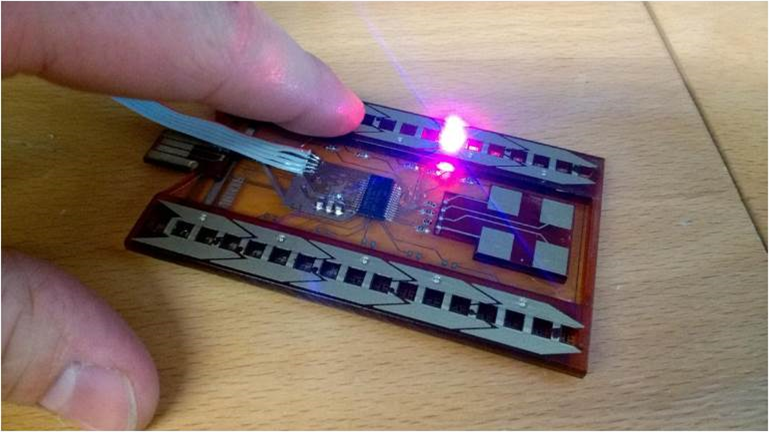

Rapid Electronics Design and Prototyping

Beat out the competition by developing new electronic products to market faster than ever before. Rapid prototyping of electronics significantly compresses part development times and allow for a higher frequency of iterations for better products in less time.

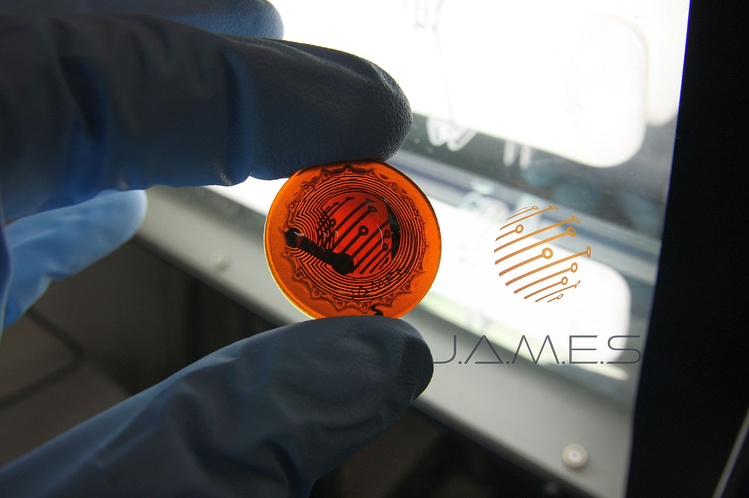

High-End PCB Assembly

Printed circuit boards (PCBs) – whether made additively or traditionally — can be completed using the Essemtec SMT Pick-and-place automation, customized to your needs. These agile production machines are scalable for extended, integrated assembly lines.

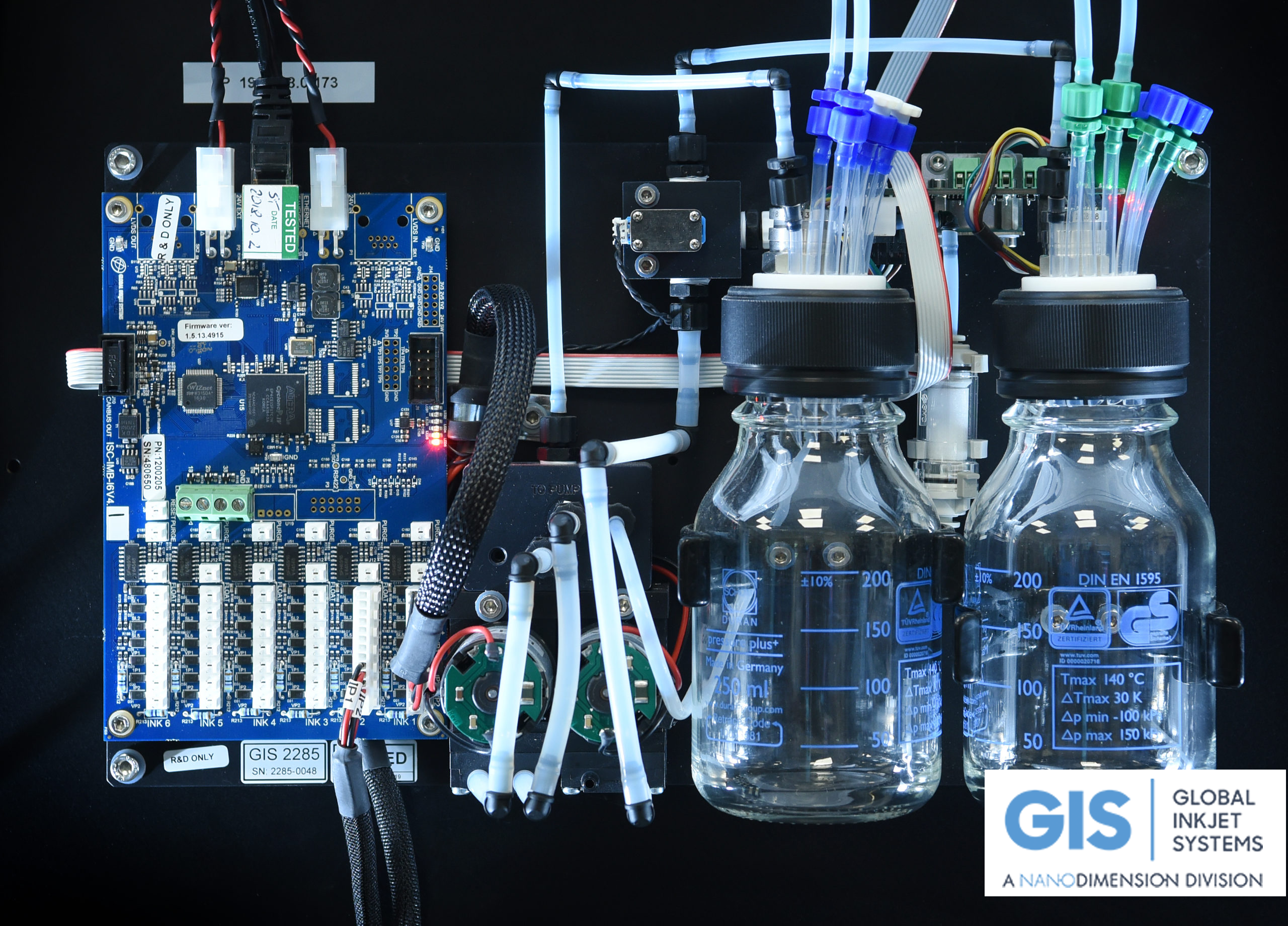

Advanced Inkjet Printing for Part Completion

Optimize product completion with new advanced Direct-to-Shape inkjet printing technologies for protective finishing product exteriors via our Global Inkjet Systems division.