Compact AME Multilayer Bandpass Filter For Circuit-In-Package for X-Band radio frequency front-end

An example of circuit-in-a-package innovation for 5G IoT applications

The upcoming wireless ecosystem will deploy billions of high-speed wireless devices in a dynamic environment. Undoubtedly the new era of 5G IoT will require a different class of high-performance electronic components and communication hardware that is lightweight, low-cost, quick to produce, and easily customizable for a range of potential real-world applications.

It’s very likely additive manufactured electronics (AME) will be central to building the next generation of highly integrated device antennas. The current high cost and long cycle of production for mm-wave antenna-in-package (AiP) makes proof-of-concept customized prototyping difficult. AME also fulfills the urgent need for high-speed steerable multi-beam mobile antennas. Further, additive methods are able to pack electronics and associated antenna arrays into more compact and streamlined form factors without losing critical performance.

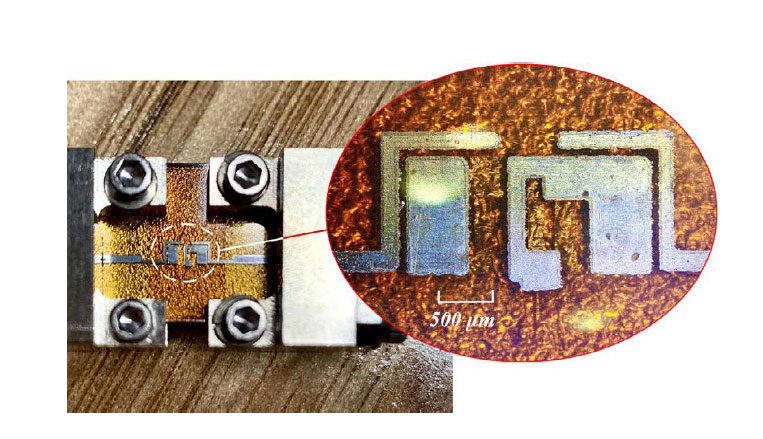

This cooperative project with our friends at UTS in Sydney shows how AME from Nano Dimension’s comprehensive DragonFly system demonstrated all these advantages over traditional PCBs in its proof-of-concept development and testing of a Bandpass Filter (BPS), using a multilayer circuit-in-a-package design approach.

Fill out the form to download the study today