1-MICRON

1

µ

precision opens up new vistas in miniturization

FASTER

80

%

production of micro devices compared to traditional methods

ITERATE IN-HOUSE

MOQ =

1

With ROI in the first few months

Reinvent medical devices in your lab

Groundbreaking technology that provides researchers the freedom to instantly create and innovate

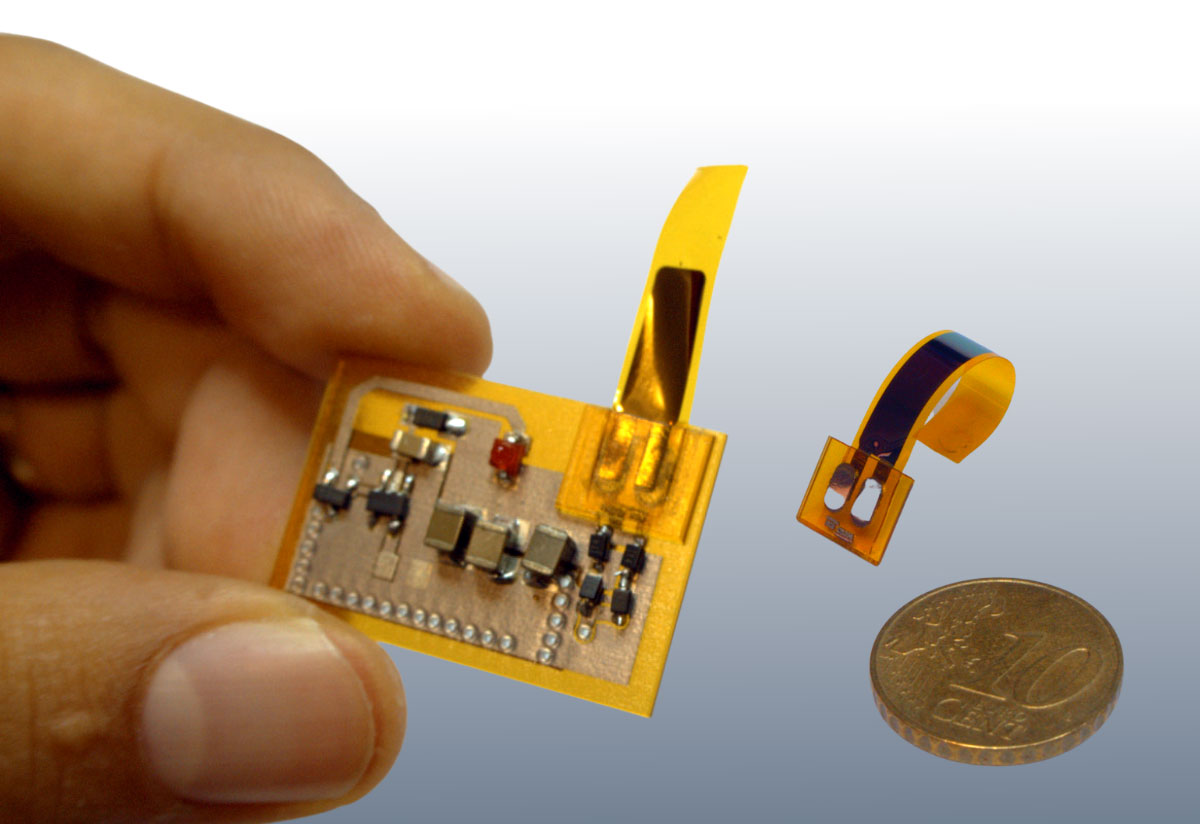

Nano Dimension’s DragonFly prints fully functional 3D electronic circuitry in-house.

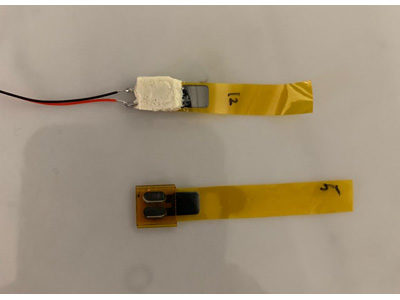

Researchers can also explore free-form printing of metals and dielectric polymers for entirely new applications.

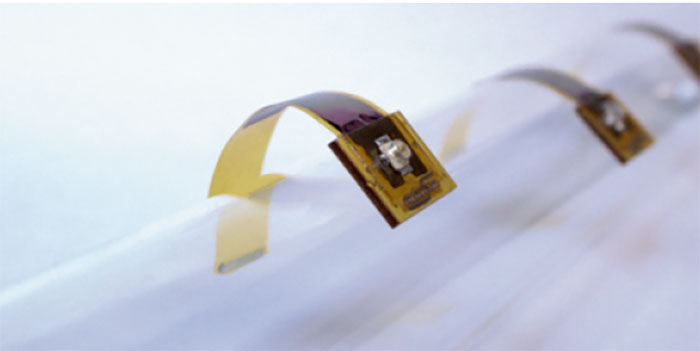

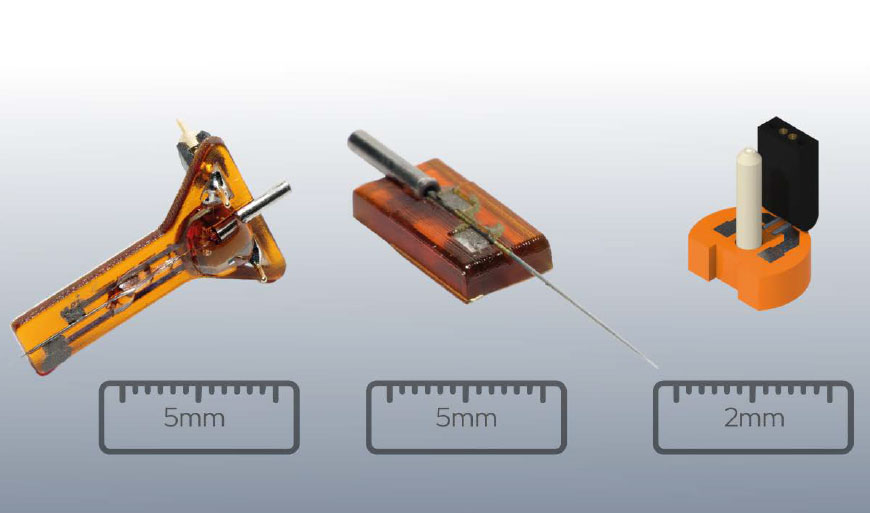

Unprecedented Form Factors

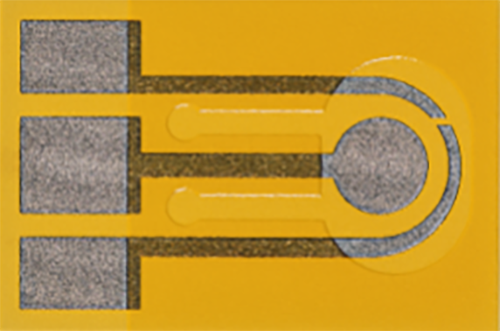

Multiply layers and freely form connections inside 3D electronic devices

High

High

Performance

Fabricate embedded antennas, coils and other high-performance passive components

Short

Development

Cycles

Immediately test in-house, proofs of concept at low cost