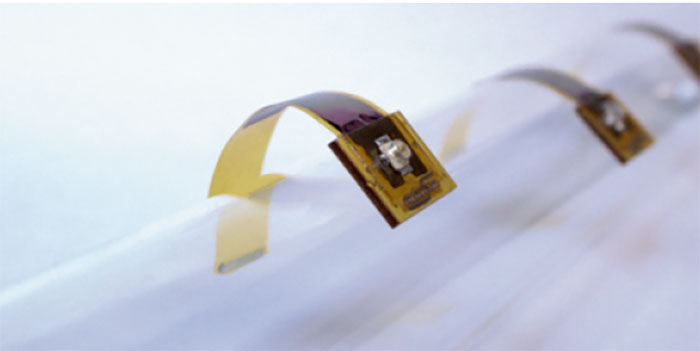

Unlocking the Power of AME by Integrating Electrical (ECAD) and Mechanical Data (MCAD).

____________________________________________________________________________________________

Push the boundaries of electronics manufacturing

Flight Hub is not just software; it’s a transformational tool that is set to redefine the landscape of electronic product development. It facilitates the integration of mechanical and electronic design in ways that were not possible before.

Explore the boundless potential of your designs with Flight Hub and join us on this exciting journey into the future of additive manufacturing electronics. Whether you are looking to innovate in consumer electronics, automotive, aerospace, or any other industry, Flight Hub provides the tools you need to turn visionary ideas into reality.

____________________________________________________________________________________________

SELECTED FEATURES

Component Factory

Parametrical creation of AME components

Parametrical Creation of AME Components

This capability revolutionizes the design process, allowing designers to create complex electronic components with unprecedented flexibility and efficiency.

With Flight Hub’s parametric design tools, designers can easily customize AME components to meet specific requirements and preferences. Whether it’s adjusting dimensions, modifying shapes, or fine-tuning electrical properties, Flight Hub empowers designers to iterate rapidly and explore a wide range of design variations.

Digital Manufacture

Automatically Sliceable Manifold 3D Designs

Automatically Slice and Check Design Rules

Flight Hub offers the groundbreaking ability to automatically slice manifold 3D designs, revolutionizing the additive manufacturing process. This feature simplifies the preparation of designs for printing, eliminating the need for manual intervention and ensuring optimal print quality. Designers can focus on creativity and innovation, knowing that Flight Hub seamlessly handles the technical aspects of design preparation.

Parts Library

Flight Hub simplifies the generation and management of 3D manufacturing files, streamlining collaboration within your company.

Easy Generation and Efficient Management

Flight Hub offers an intuitive interface for effortlessly generating 3D manufacturing files. Designers can easily convert their designs into compatible formats such as STL, OBJ, or STEP with just a few clicks. This streamlined process ensures that manufacturing files are quickly generated, reducing downtime and accelerating the production timeline.

Flight Hub provides a centralized platform for managing 3D manufacturing files within your company. Designers can organize files into folders, assign access permissions, and track version history, ensuring that everyone has access to the latest files and updates. This efficient management system promotes collaboration and prevents confusion, ultimately improving workflow efficiency.

Four Key Objectives

Register for the Early Access Program

DragonFly IV + FLIGHT Hub Tech Specs and Capabilities

- Dimensions

1,400mm x 800mm x 1,800mm - Weight

520kg, (1,150lbs) - Power Supply*

230VAC, 20A, 50–60Hz - Network Connectivity

Ethernet TCP/IP 10/100/1000 - Operational Humidity

Above 35% non-condensing - Operational Temperature

18°C (64°F) to 28°C (82°F) - Regulatory Compliance

UL, CE, FCC - Deposition Technology

Piezo drop-on-demand inkjet - Number of Printheads

2, one for each ink: conductive and dielectric - Software

FLIGHT Software Suite (Design, Verification, Pre-Production)

- Build Volume

160mm x 160mm x 3mm - Inks

Optimized silver nano particles and dielectric inks - Supported File Formats

All major ECAD and MCAD Software, ODB++, Gerber & Excellon, STLs - Resolution

18 µm (x), 18 µm (y), 10 µm (z) - Min. Line/Space

75 μm traces/ 100 μm spacing - Min. BGA Pitch

350 μm - Min. Via

150 µm - Min. Dielectric Layer Thickness

10.0 μm - Min. Conductive Layer Thickness

1.18 μm - Conductivity (Relative to Copper)

30% +/-5% - Dielectric Constant (Dk) @ 2 GHz/15 GHz

2.77 / 2.78 - Tangential Loss (Df) @ 2 GHz/15 GHz

0.015 / 0.018

* Must use UPS (Uninterruptible Power Supply)

This data represents typical tested values at a controlled environment. Material properties can vary with part geometry, print orientation, print settings, environmental conditions and additional variables. To learn more about specific testing conditions, please contact a Nano Dimension representative. Specific performance of customer parts should be tested in accordance with customer’s specifications.

The above detailed data was tested, measured, or calculated using standard methods based on, inter alia, ASTM and IPC standards and are subject to change without notice. To the fullest extent permissible pursuant to applicable law, Nano Dimension (including any affiliate thereof) disclaims all warranties of any kind, express or implied. The above detailed data should not be used to establish design, quality control, or specification limits, and is not intended to substitute customer’s own testing to determine suitability for a particular application.