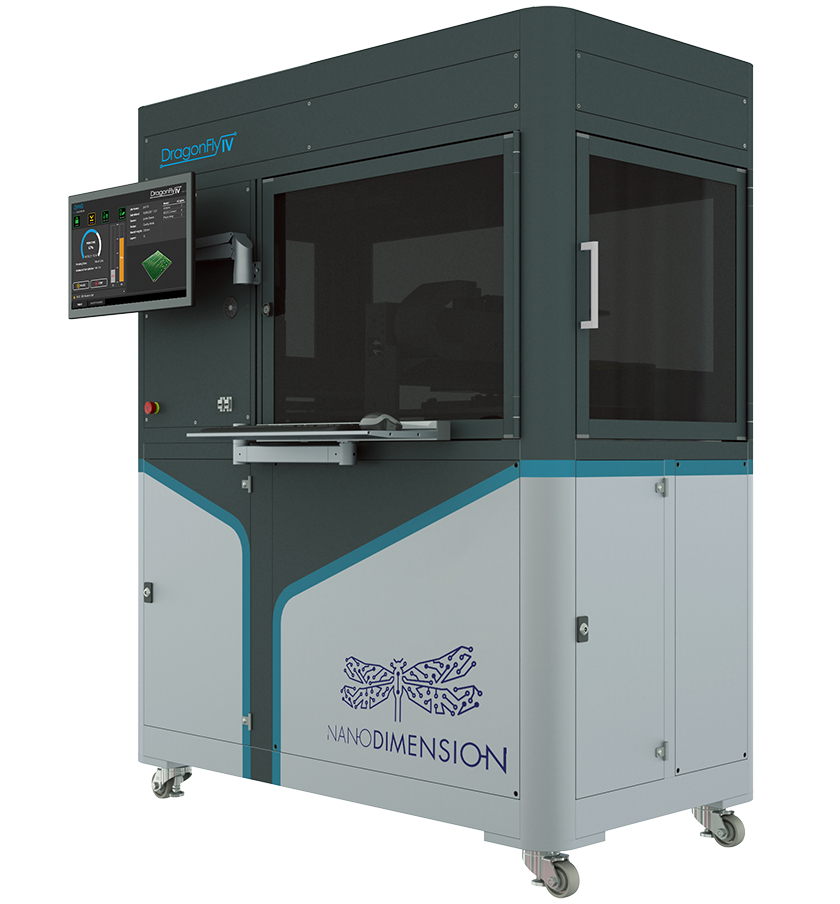

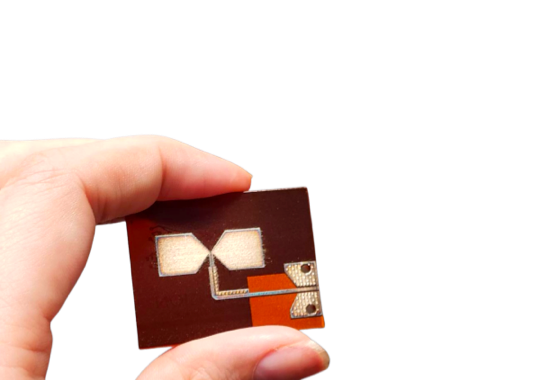

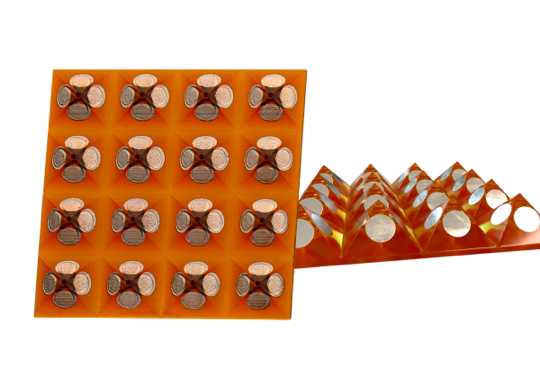

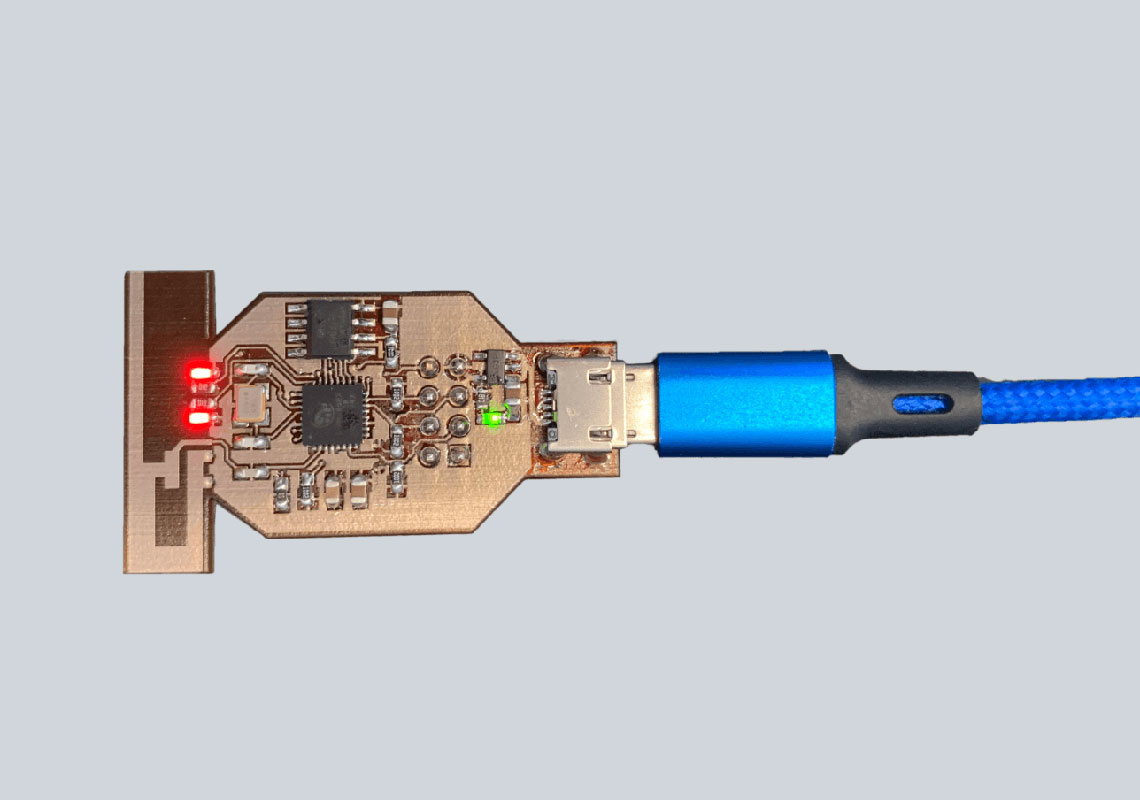

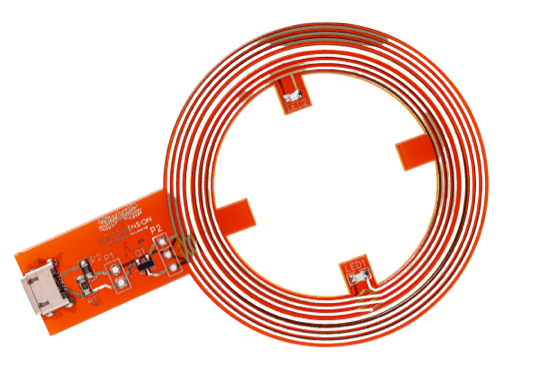

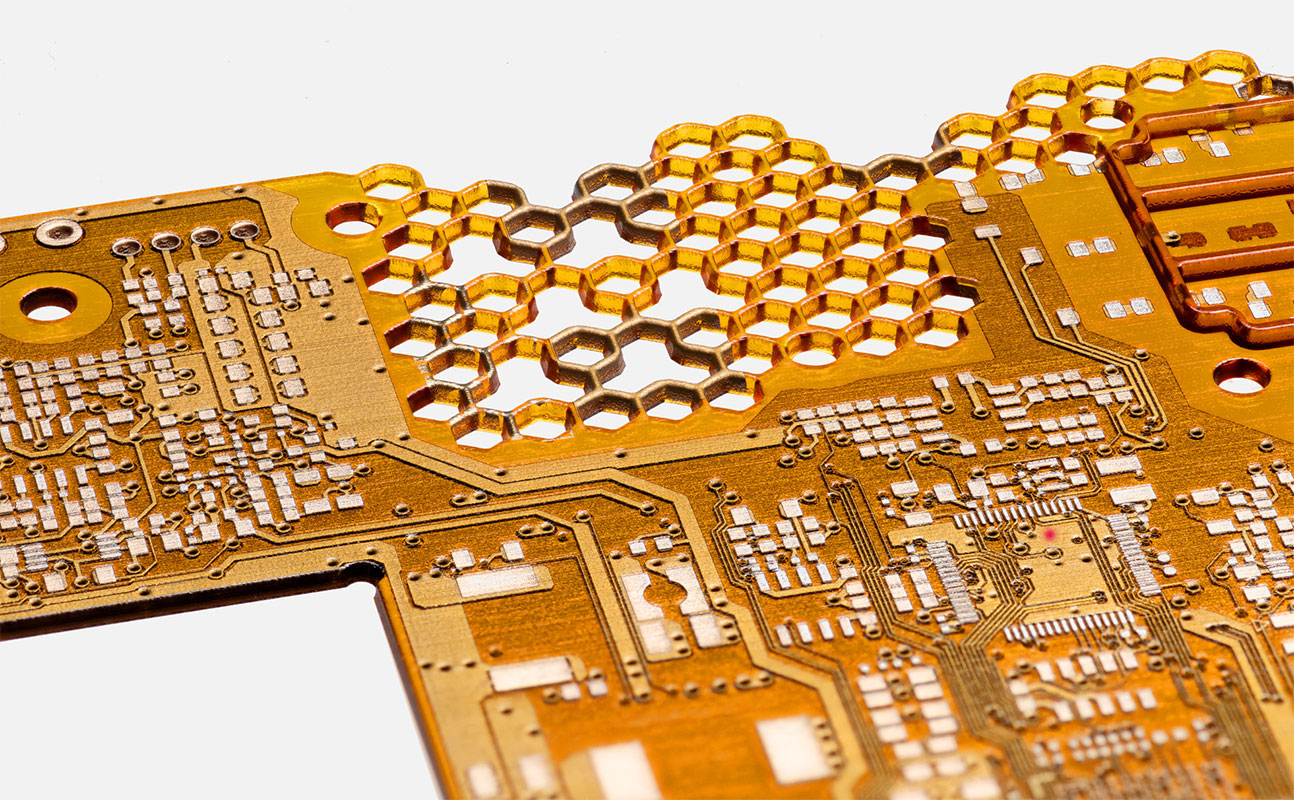

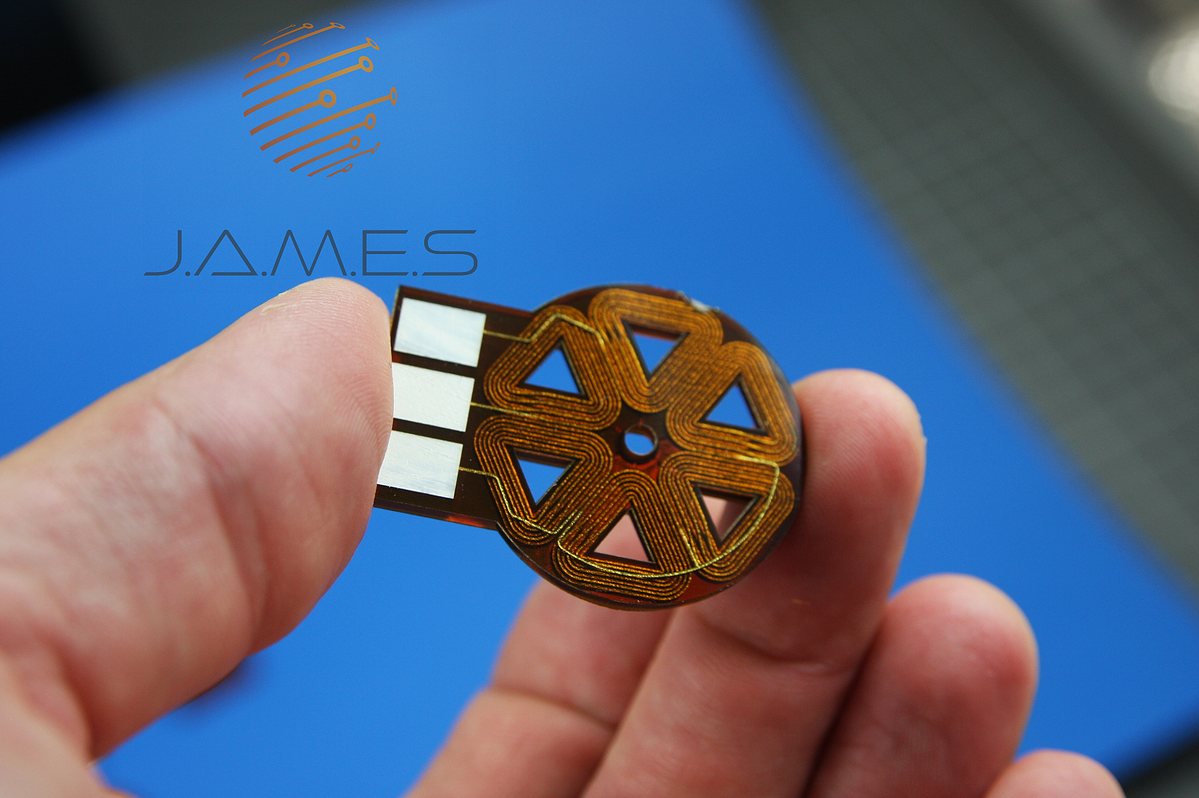

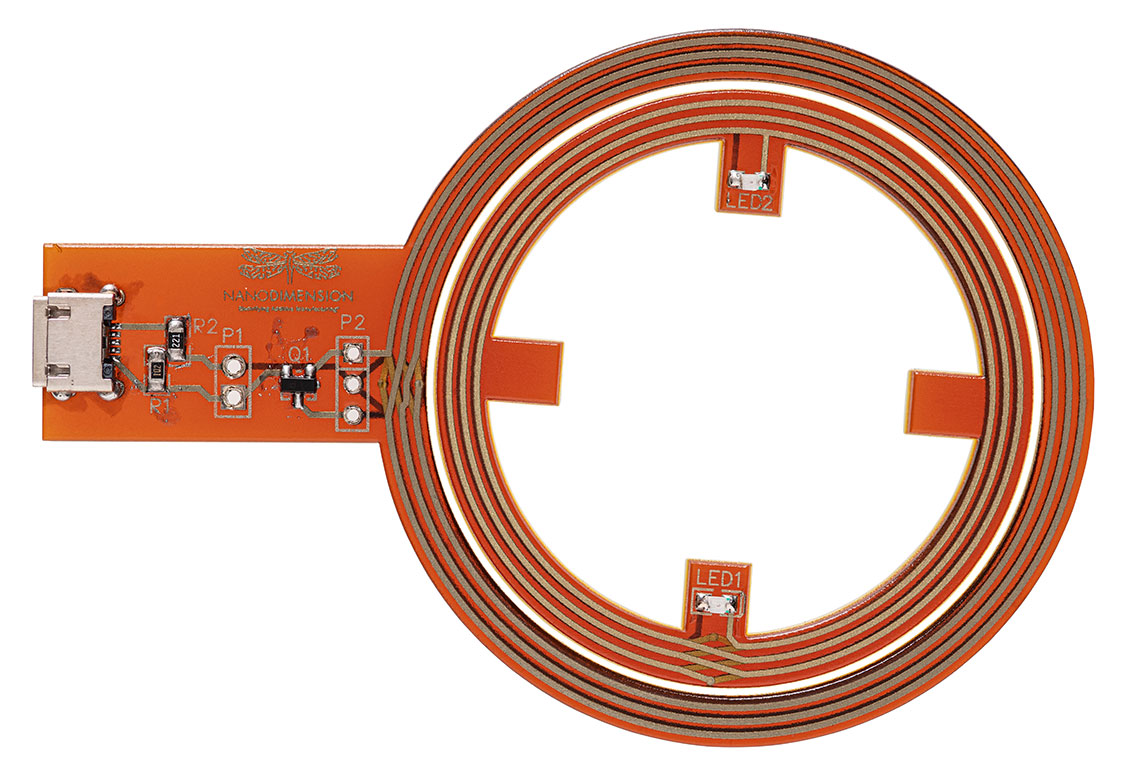

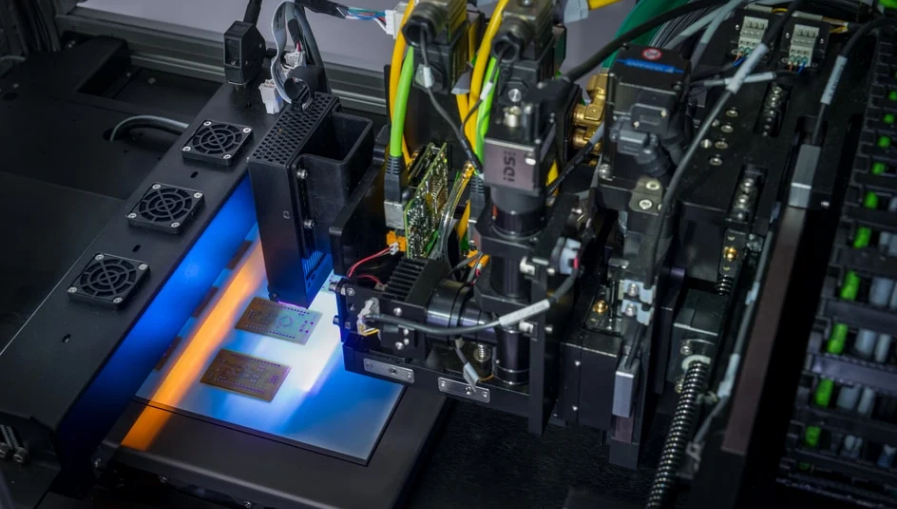

A multi-material, multi-layer 3D printer that generates entire circuits in one step — including substrate, conductive traces, and passive components

____________________________________________________________________________________________

Design Flexibility Beyond Traditional Boundaries

A completely new way to build electronics

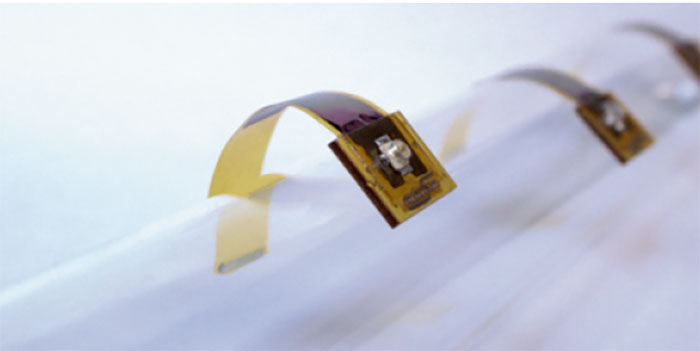

Freedom in Three Dimensions

Layouts can now make connections in any 3D direction

Novel Form Factors

FLIGHT software allows for new shapes in electro-mechanical CAD

Transformational Processes

Highly agile design and production in days, not weeks or months

Digital End-to-End Execution

Additively Manufactured Electronics (AME) removes human error and lengthy manual operations

Cleaner Methods

3D printing eliminates toxic chemical waste and dramatically reduces energy consumption

Generate Devices in House

Turn ideas into fully functional circuits within hours

Protect Your IP

Keep ideas confidential within your organization

High Performance

Component electrical performance is comparable to traditional devices

Guided by Deep Learning

DeepCube — the first AI devoted to additive manufacturing

Better Yield

Self-learning artificial intelligence dramatically improves printed output

Real-Time Correction

DeepCube can detect and correct for small defects during production

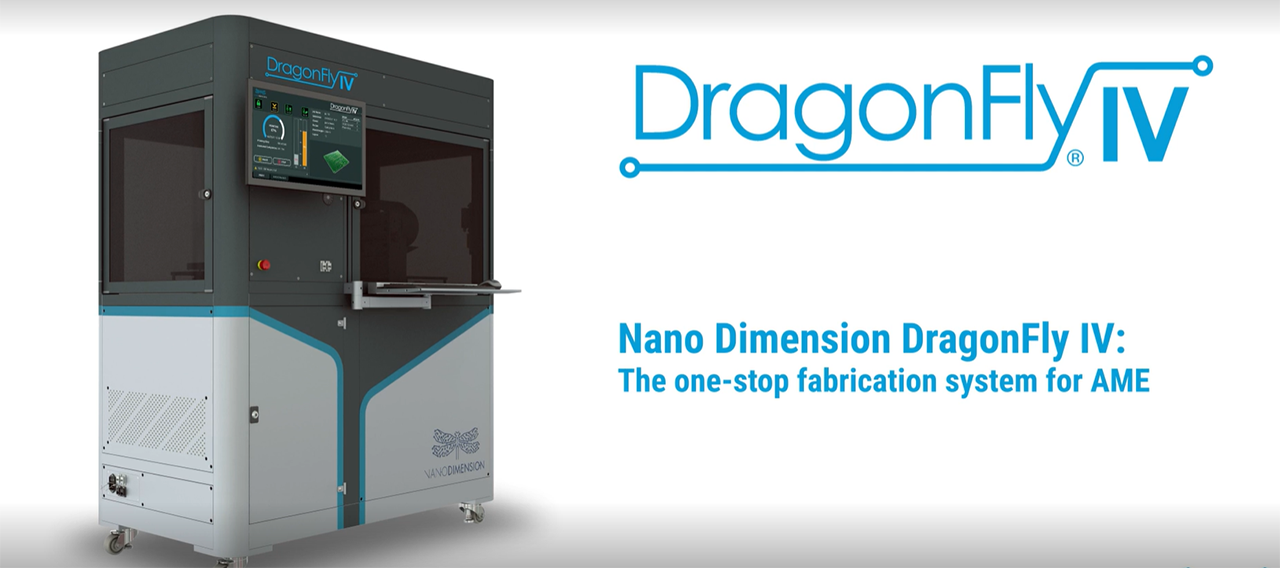

DragonFly IV Tech Specs and Capabilities

- Dimensions

1,400mm x 800mm x 1,800mm - Weight

520kg, (1,150lbs) - Power Supply*

230 VAC, 20A, 50–60Hz - Network Connectivity

Ethernet TCP/IP 10/100/1000 - Operational Humidity

Above 35% non-condensing - Operational Temperature

18°C (64°F) to 28°C (82°F) - Regulatory Compliance

UL, CE, FCC - Deposition Technology

Piezo drop-on-demand inkjet - Number of Printheads

2, one for each ink: conductive and dielectric - Software

FLIGHT Software Suite (Design, Verification, Pre-Production)

- Build Volume

160mm x 160mm x 3mm - Inks

Optimized silver nano particles and dielectric inks - Supported File Formats

All major ECAD and MCAD Software, ODB++, Gerber & Excellon, STLs - Resolution

18 µm (x), 18 µm (y), 10 µm (z) - Min. Line/Space

75 μm traces/ 150 μm spacing - Min. BGA Pitch

400 μm - Min. Via

200 µm - Min. Dielectric Layer Thickness

10.0 μm - Min. Conductive Layer Thickness

1.18 μm - Conductivity (Relative to Copper)

30% +/-5% - Dielectric Constant (Dk) @ 2 GHz/15 GHz

2.77 / 2.78 - Tangential Loss (Df) @ 2 GHz/15 GHz

0.015 / 0.018

* Must use UPS (Uninterruptible Power Supply)

This data represents typical tested values at a controlled environment. Material properties can vary with part geometry, print orientation, print settings, environmental conditions and additional variables. To learn more about specific testing conditions, please contact a Nano Dimension representative. Specific performance of customer parts should be tested in accordance with customer’s specifications.

The above detailed data was tested, measured, or calculated using standard methods based on, inter alia, ASTM and IPC standards and are subject to change without notice. To the fullest extent permissible pursuant to applicable law, Nano Dimension (including any affiliate thereof) disclaims all warranties of any kind, express or implied. The above detailed data should not be used to establish design, quality control, or specification limits, and is not intended to substitute customer’s own testing to determine suitability for a particular application.