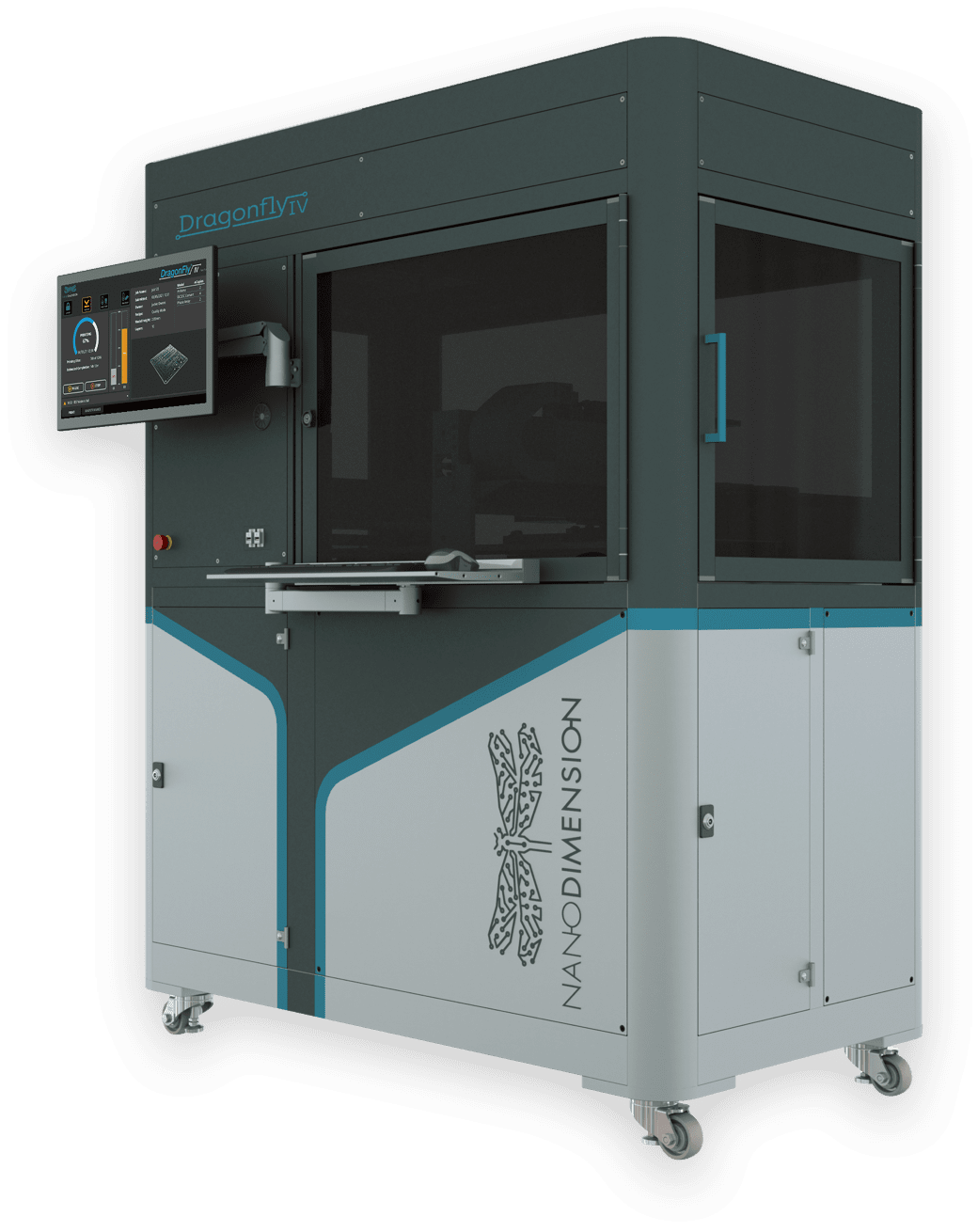

Generate Cutting-Edge Electronics in Your Lab

Groundbreaking technology that provides researchers the freedom to instantly create

Generate fully functional 3D printed electronic circuitry in-house. Explore research and product concepts with the free-form printing of metals and dielectric polymers.

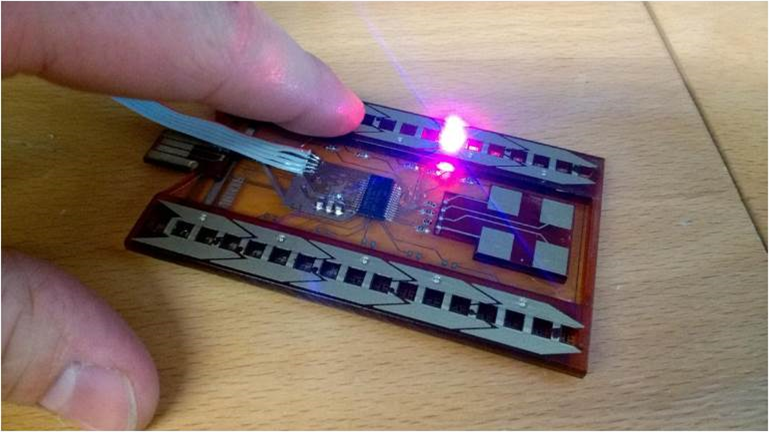

A New Range of

Form Factor

Use true 3D design space to make electronic devices

High

Performance

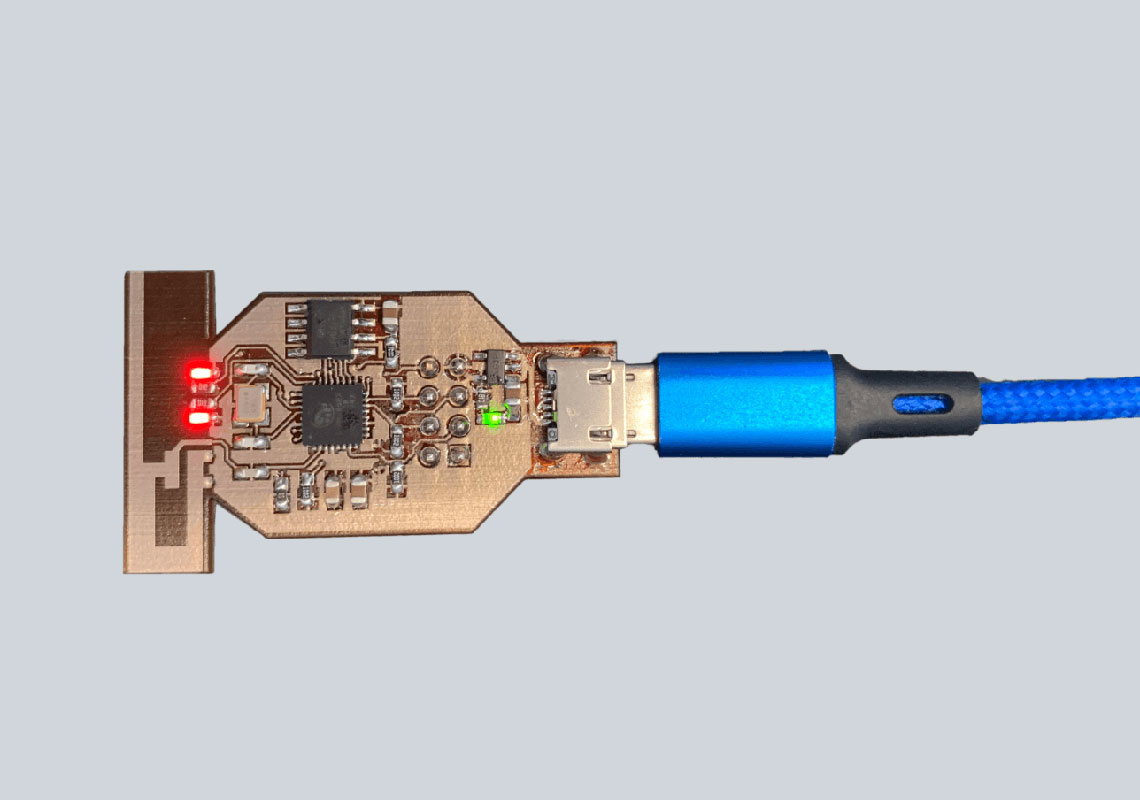

Embed components as good or better than off-the-shelf parts

Shorter

Cycles

Iterate and test validity of concept in house without delays