Redefining production with digital manufacturing solutions.

A Message of Focus. A Commitment to You.

A digital manufacturing strategy that uses industrial 3d printed electronics to succeed

Innovation

A Cleaner Future

Faster Go-to-Market

Design products like never before

- Remove design constraints for new applications and unique shapes in 3D space

- Explore possibilities in part miniaturization and weight reduction

- Deliver new, previously unimagined parts and devices for electronics, aerospace, medical and other industries

Cleaner processes

Nano Dimension’s AME platform delivers significant environmental improvement over traditional production:

- 82% less chemicals used

- 98% less raw materials used

- 57% less energy

- 99% less waste

Rewrite the economic equation for production

- Take days, not weeks or months, to generate new prototypes

- Significantly save time and costs through tool-free, low-volume high-mix processes

- Reduce reliance on supply chains through localized and distributed production

- Eliminate delays caused by human or machine error

Hardware and Software Solutions

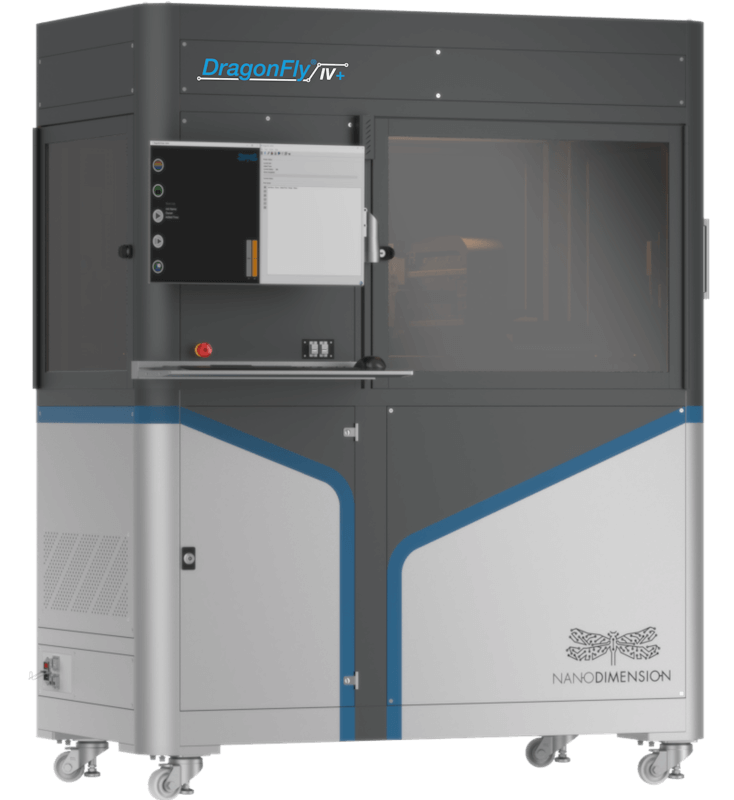

DragonFly IV+

FLIGHT Software Suite

Essemtec SMT Pick and Place

Global Inkjet Systems

Additive Printer

DragonFly IV+

Reinventing the electronics production industry with additively manufactured electronics (AME)

Learn More

3D AME Software

FLIGHT Software Suite

Bringing ECAD and MCAD together for seamless 3D electronics design to prototyping

Electronics Assembly

Essemtec SMT Pick and Place

Solutions for pick-and-place, soldering, and automated assembly of electronics

Learn More

Inkjet Technologies

Digital Deposition Technologies

Industrial Inkjet Software, Drive Electronics, Components & Services

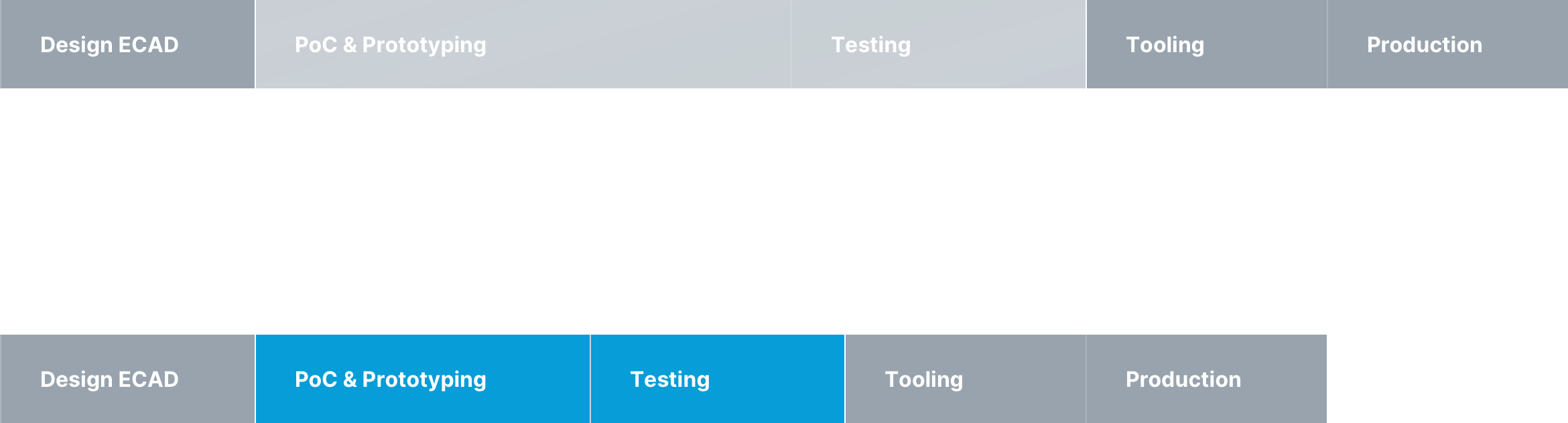

Learn MoreWe shorten the R&D and

Go-to-Market timeline

“The ability to manufacture RF systems in house offers an exciting new means for rapid and affordable prototyping and volume manufacturing.”

Dr. Arthur Paolella,

Senior Scientist, Space and Intelligence Systems, L3 Harris Corporation.

“Nano Dimension’s AME technology helped us to achieve an original product prototype and it simplified the manufacturing process compared to traditional methods.”

Dr. Francesco Guido

CTO Piezoskin S.R.L.

“To have high-density components quickly available with reduced effort by means of 3D printing gives us a competitive edge in the development process.”

Thomas Müller

CEO of HENSOLDT

“The ability of the DragonFly system to rapidly and affordably manufacture functional prototypes makes it ideal for our team.”

Prof. Massimo De Vittorio

CBN-IIT — Lecce — Italy