Our Mission

Nano Dimension (Nasdaq, NNDM) is a provider of intelligent machines that are changing the way the world manufactures.

Our pioneering solutions are transforming design and production to match the efficiency demands of Industry 4.0.

Our vision is to reinvent a tangle of analog and manual processes into a fast, integrated, all-digital system.

Origins in Additive

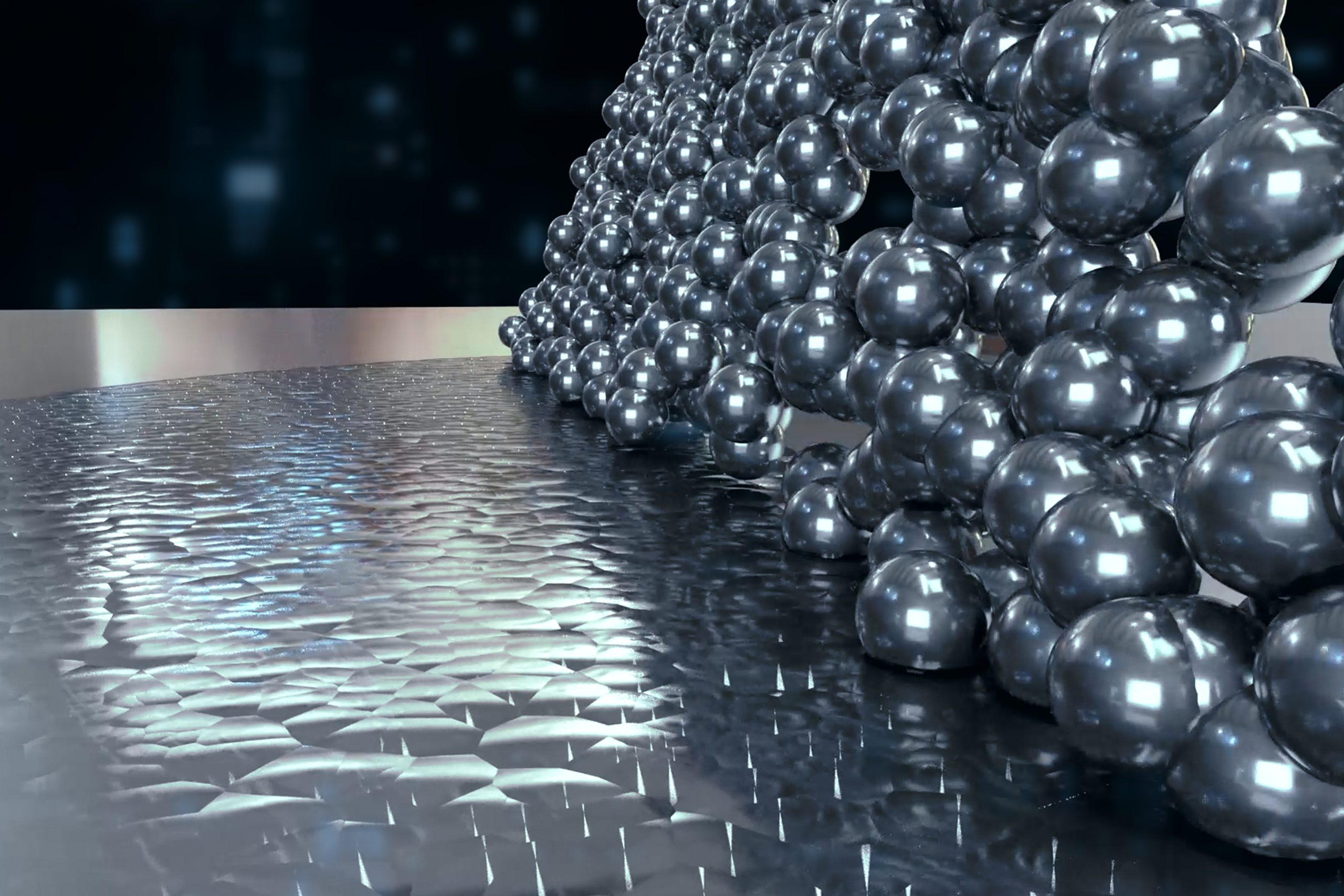

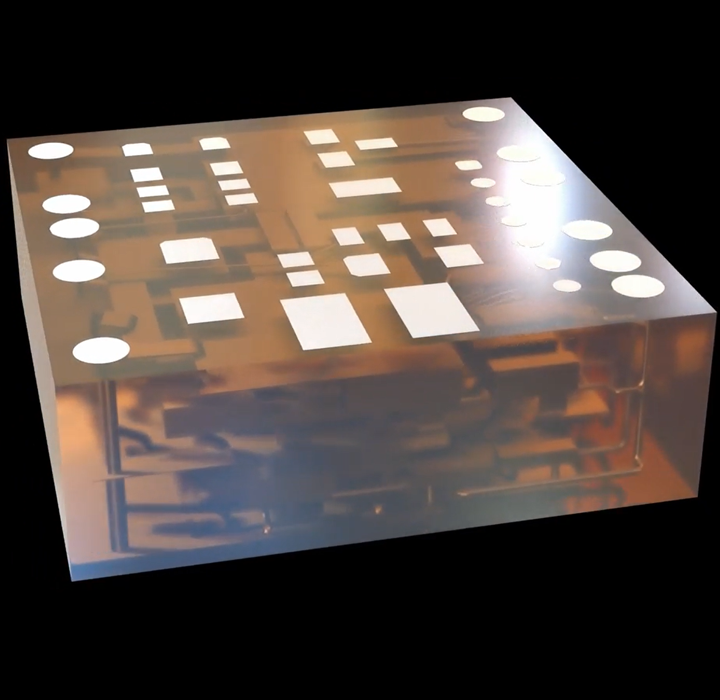

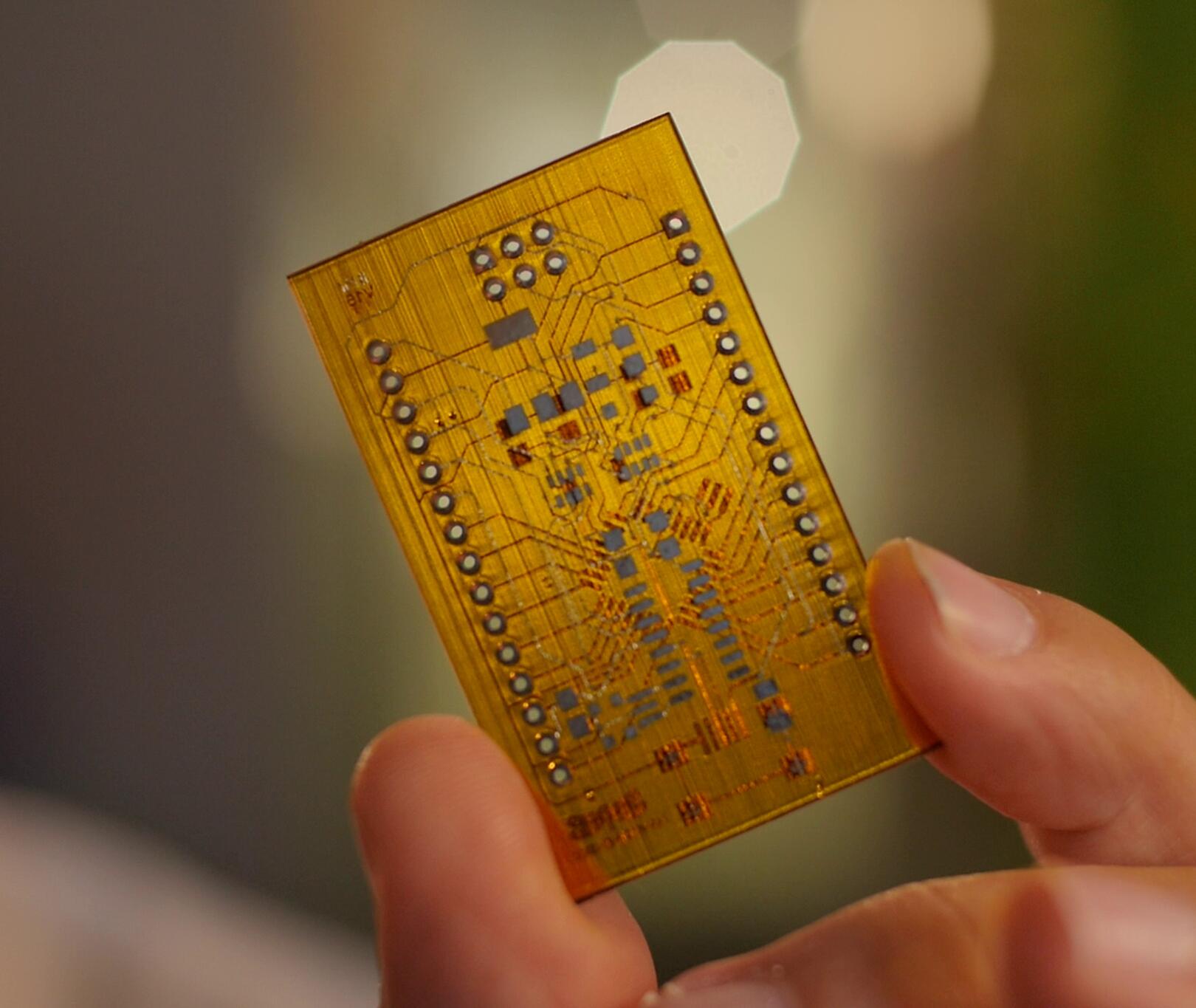

Nano Dimension is the pioneer and provider of Additively Manufactured Electronics (AME) technology – an alternative in-house method of fabricating printed circuit boards (PCBs) and other electronic devices.

We’re also not just changing the scale of production, we’re changing the scale of products, with Fabrica 3D precision micro AM printers that can craft details down to the micron level.

Technological Convergence

Thanks to a series of strategic acquisitions, our unprecedented 3D printing capabilities are now integrating with the most advanced factory robotics and the latest developments in hardware and software, including neural-network Deep Learning AI.

A Company of Inventors — for Inventors

Our technologies will enable R&D labs new latitude to develop products that are radically innovative.

Designers and engineers in medicine, aerospace, scientific research, and electronics are using our solutions to create today what was impossible yesterday.

At Nano Dimension, we’re inventing something completely new – now so can you.