How The Center for Biomolecular Nanotechnologies Uses AME

The Center for Biomolecular Nanotechnologies (CBN ITT) develops micro and nanotechnologies for monitoring and controlling health, wellness, sport performance and living environments.

Wearable medical device research and development in Academia is delivering the next evolution of electronic applications.

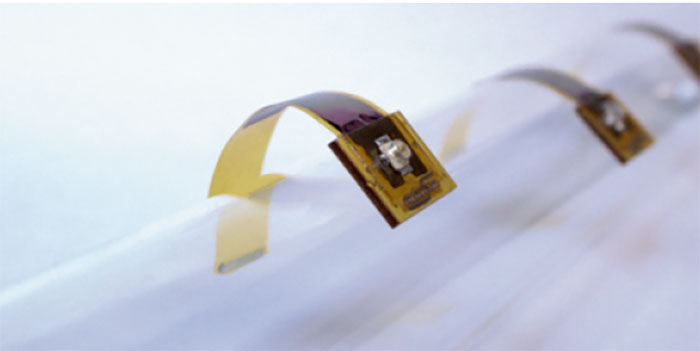

Using custom flexible materials, the DragonFly 3D printer can generate new and novel research of circuits that conform to organic or custom shapes.

Current research includes smart patches and tattoos for on-skin testing.

With Additively Manufactured Electronics (AME),

AME enables greater acceleration of medical research not only through the use of 3D space but in the ability to rapidly iterate and produce prototype for testing.

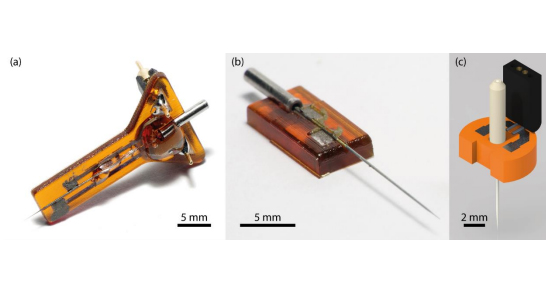

Implantable optoelectronic probes combine light delivery with electrodes for the readout of electrochemical signals, are an ideal candidate for 3D printed electronics.

By combining miniaturization with use of the 3D space, new variations can be prototyped immediately for testing and evaluation.

Nano Dimension 3D printers enable extensive research and innovation into new devices for medical and life sciences.

Additively Manufactured Electronics (AME) deliver new opportunities for innovation and research into Lab on Chip devices.

By utilizing true 3D space and opportunities for miniaturization, AME can bring new, novel and innovative Lab on Chip devices to life.

Advances in medical device research are demanding ever-smaller mechanical parts at far greater precision. Nano Dimension’s Fabrica precision micro-additive manufacturing system delivers micron-level plastic parts production at 10 times the speed as other platforms.

Read About how AntiShock uses Micro 3D printing for medical device prototyping