Services Hotline

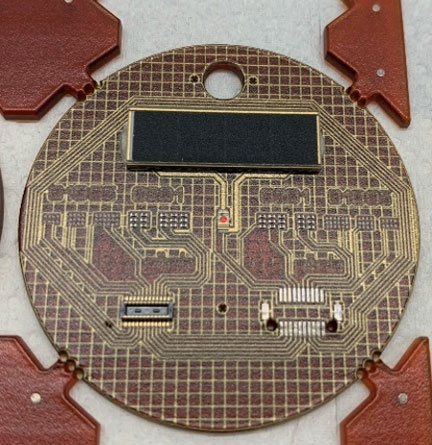

DragonFly & Fabrica Support, USA

Contact our Nano Dimension Service Hotline for questions on pricing, shipping and services.

Hours: Mon-Fri, 10am-5pm (ET)

Phone: +1 408 824 8242

Email: support@nano-di.com

Essemtec USA Support

Contact our Essemtec Service Hotline for questions on pricing, shipping and services.

Hours: Mon-Fri 10am-5pm (ET)

Phone: +1 (856) 218 1131

Business matters: sales-usa@essemtec.com

Technical support: service-usa@essemtec.com

Spare parts: spares-usa@essemtec.com

Order processing: orders-usa@essemtec.com

Invoices and payments: finance-usa@essemtec.com

Visit the Customer Learning Center

Technical sessions, manuals, how-to guides and more (Login required)

Talk to a Sales Expert

Visit our Contact Us Page